Good afternoon.

I have a question about working with numeric variables when writing an ZPL macro. Is it possible to round the values assigned to variables with the required accuracy? I'm looking for functions similar to (FLOOR.MATH) and (CEILING.MATH) in Microsoft Excel.

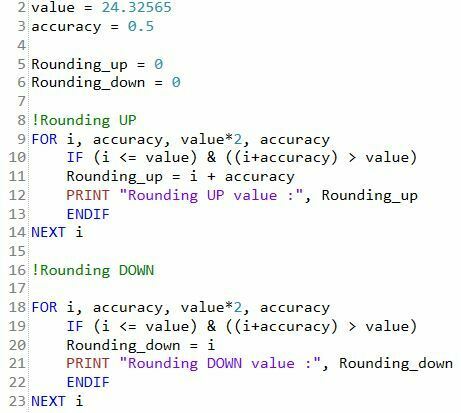

I understand that i can create a loop that allows me to sequentially compare the value of interest with i and i+1 value. I would like to create an ZPLM operand using rounding, so it seems to me that this way will slow down the optimization, especially with a high degree of rounding accuracy.

As an example, we can discuss the case where the value 24.432 needs to be rounded up to 24.0 or 24.5.