In a previous Tech Tip Tuesday we discussed some of the analyses available in OpticStudio to evaluate systems with freeform surfaces. For this Tech Tip Tuesday – HUD Edition: We will discuss tools available to aid with the import, conversion, and/or fitting of pre-existing freeform elements in OpticStudio.

In modern Head-Up Display systems, the optical designer is often required to incorporate some flavor of pre-existing, freeform optical element. The pre-existing element could be an airplane canopy, off-the-shelf combiner element, an automotive windshield, etc. The native data formatting of this freeform element varies by both industry application and by individual design team preference. These surfaces may have natively been created and stored as CAD files, an extended polynomial, or even just a sampled sag table. For any of these cases, OpticStudio has the answer!

- Import STEP/IGES/SAT/STL files directly

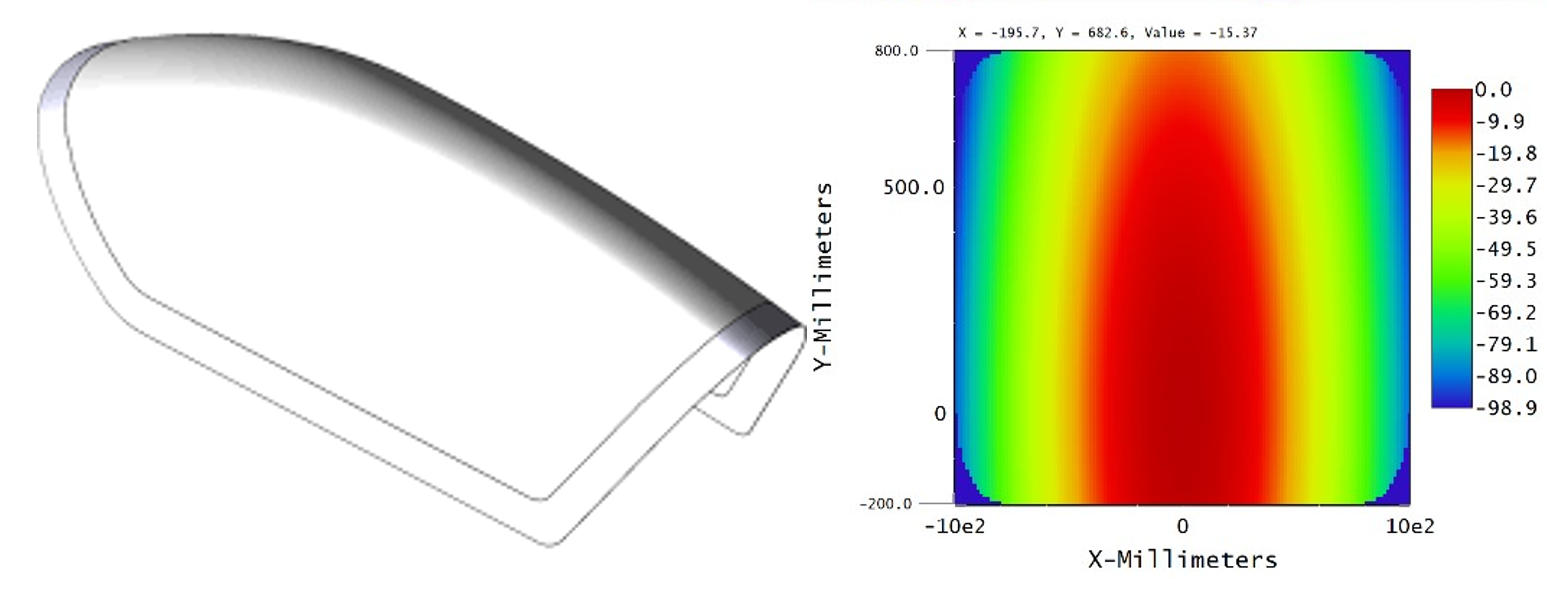

- OpticStudio is able to directly import STEP, IGES, SAT, and STL file types into Non-Sequential Mode and Mixed Mode without any loss in precision from the original CAD export.

- Convert imported CAD files to Grid Sag surfaces

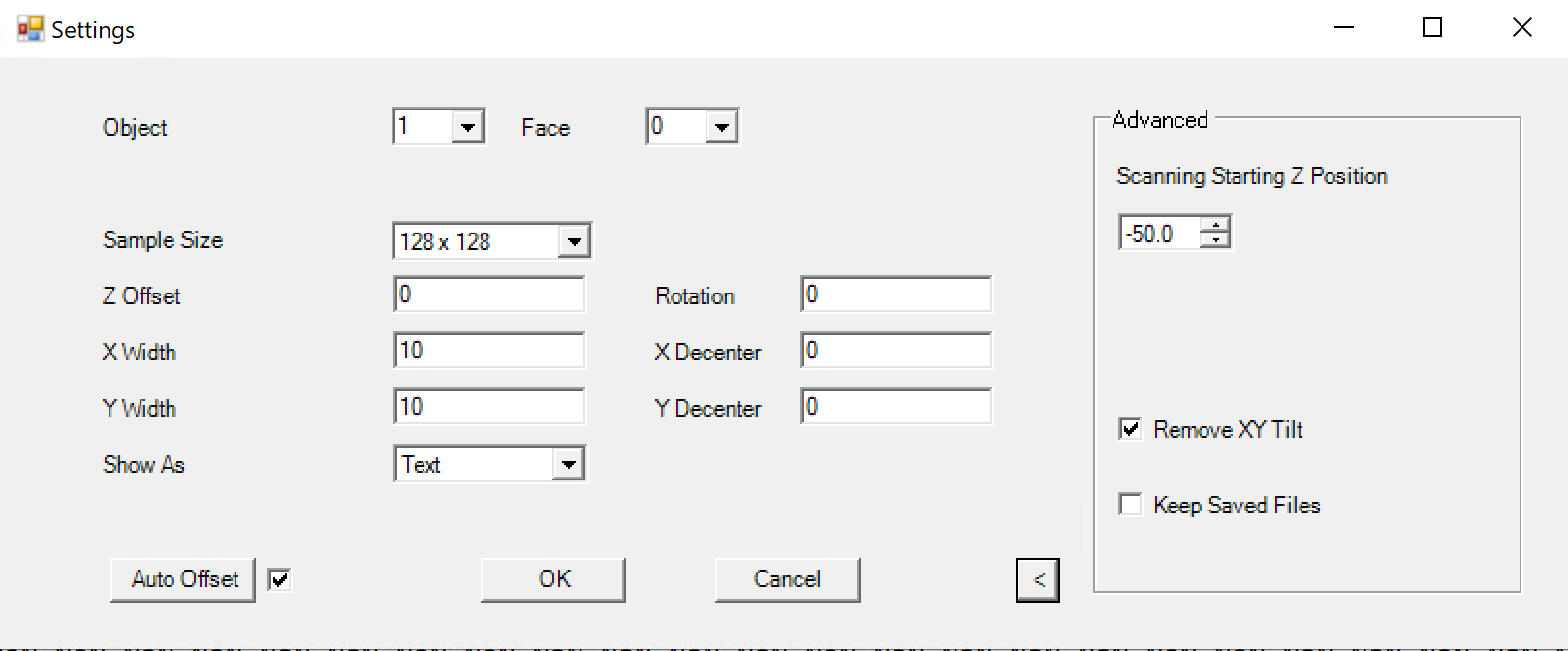

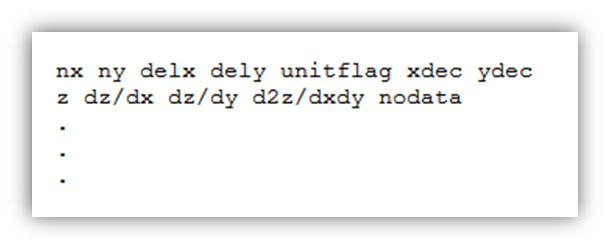

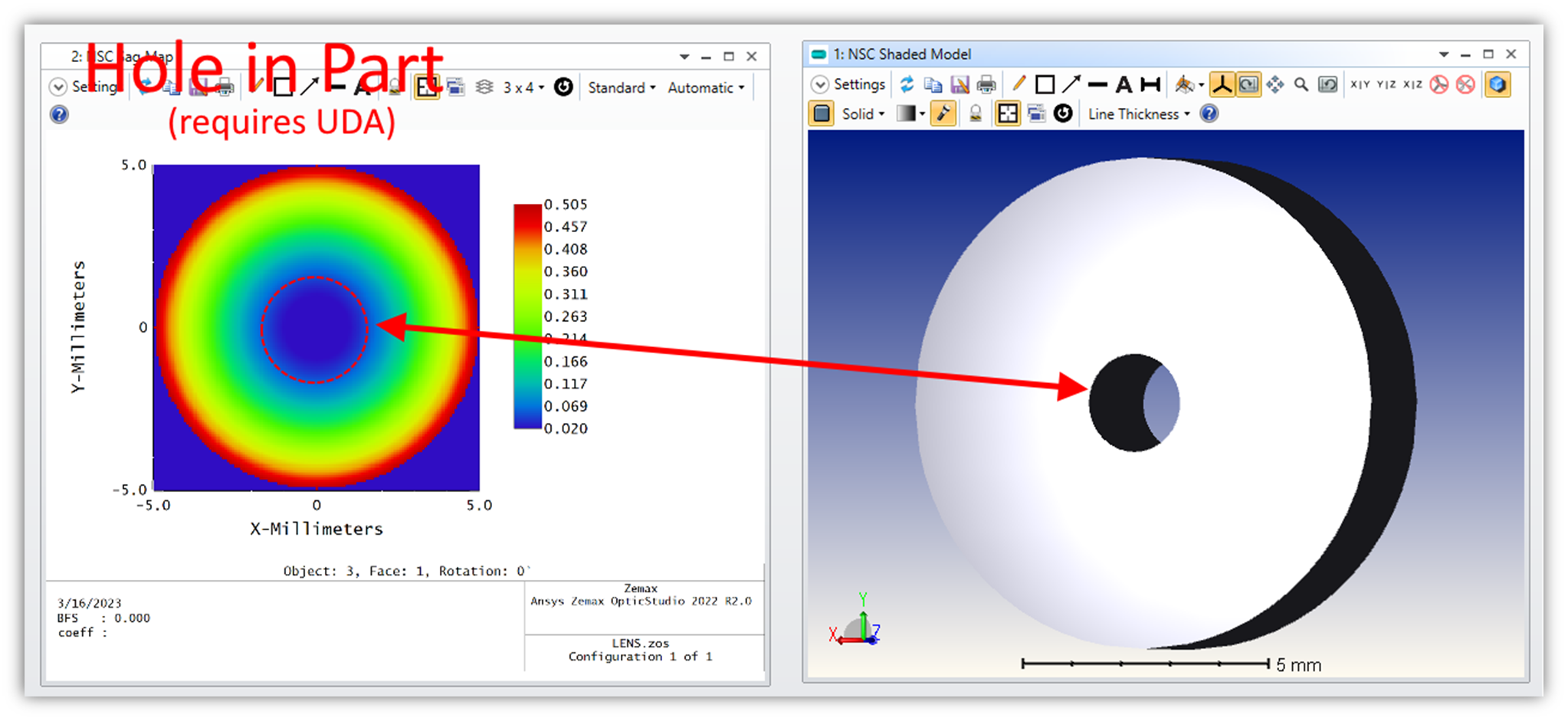

- The Non-Sequential Sag Mapping Tool can be used to generate a sag table and plot for each of the imported CAD surfaces of interest. These sag tables can now be imported into sequential mode as Grid Sag surfaces!

- OpticStudio automatically applies a bi-cubic spline fit to the tabulated data in the Grid Sag Surface file

- This freeform surface is now optimizable via the “Grid Point Optimizer”

- The Non-Sequential Sag Mapping Tool can be used to generate a sag table and plot for each of the imported CAD surfaces of interest. These sag tables can now be imported into sequential mode as Grid Sag surfaces!

- The “Convert Asphere” tool allows the designer to convert a Grid Sag surface to an Even, Extended, Q-Type 0, or Q-Type 1 aspheric surface.

- The freeform surface is now parametrized

- The freeform surface is now optimizable with all optimizers in OpticStudio