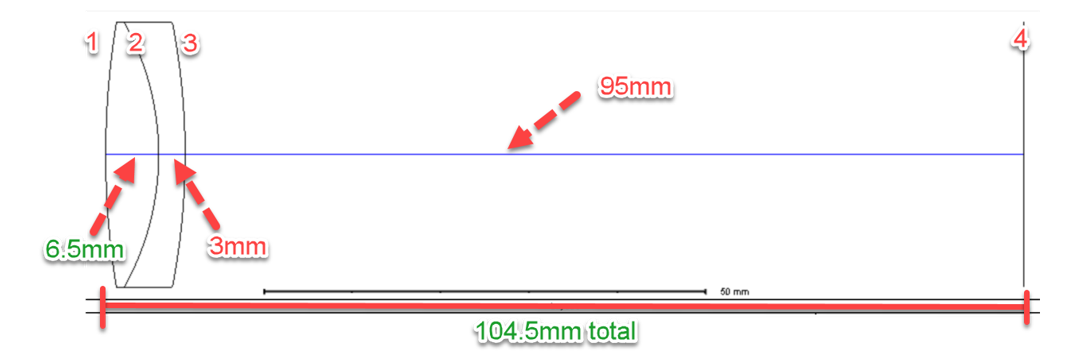

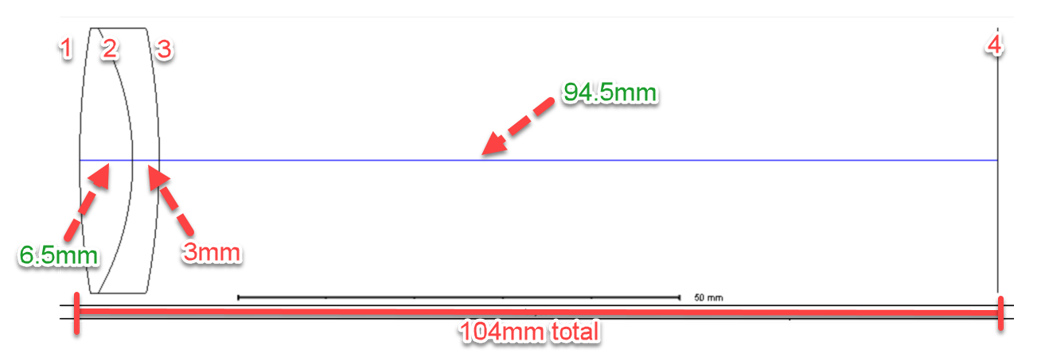

Imagine the doublet as pictured below. (Surface numbers and thicknesses shown)

fig.1.

This would be the nominal system.

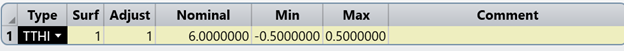

If we want to manufacture this system, we will have to tolerance these thickness values. Let’s say the thickness on Surface 1 comes back from the manufacturer and is measured to be 6.5mm. We could put the system together in one of two ways.

First, we could just make the whole system longer by the 0.5mm like so.

fig.2.

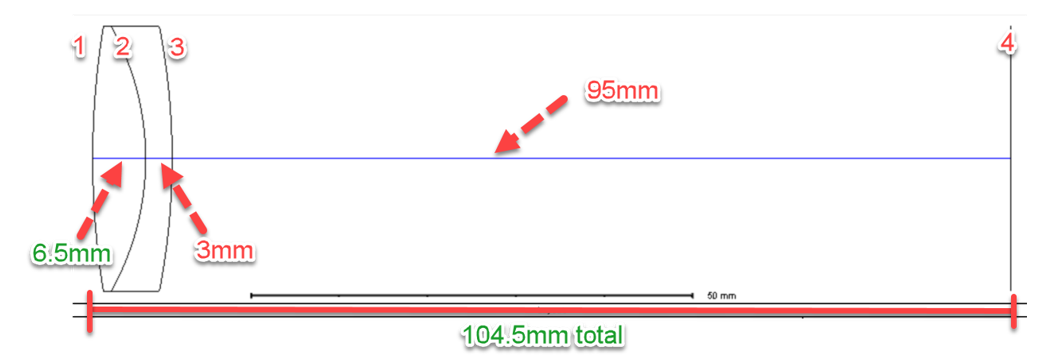

Or, we could make the thickness on surface 3 shorter by 0.5mm and have the total length remain at 104mm.

fig. 3.

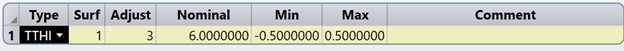

This choice is up to the design and the designer, but this is where the ‘Adjust’ parameter comes in. If we don’t want to adjust any thicknesses to make up for the change of thickness on Surface 1, we would just input the same surface value in the adjust column. This will correspond to the system in fig.2.

If we want to adjust the thickness on Surface 3 to make up for the change, we would change the ‘Adjust’ parameter to ‘3’. This will correspond to the system in fig.3.