I am comparing the linked materials attached below.

I think the biggest setting difference between the two materials is Object Surface Thickness. So I am comparing the following two cases.

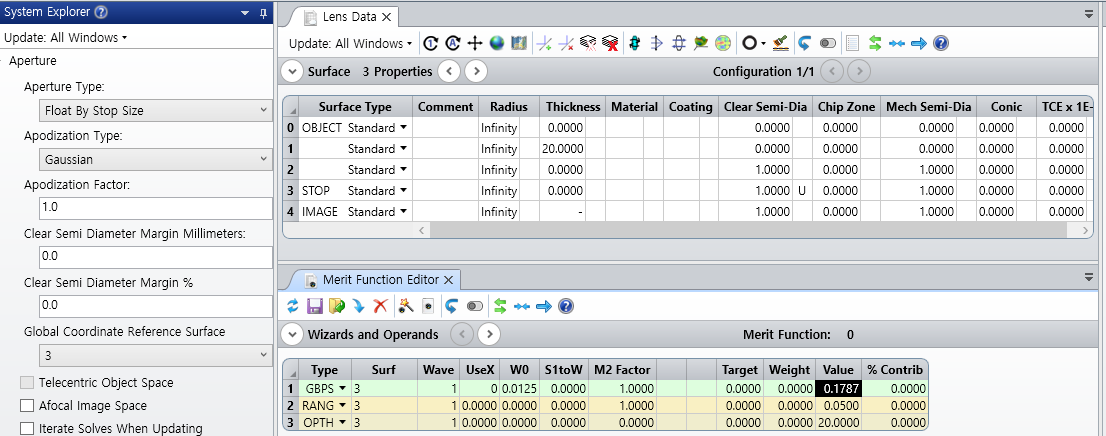

Case 1

- Surf #0 Thickness = 0

- Surf #1 Thickness = 20

- …

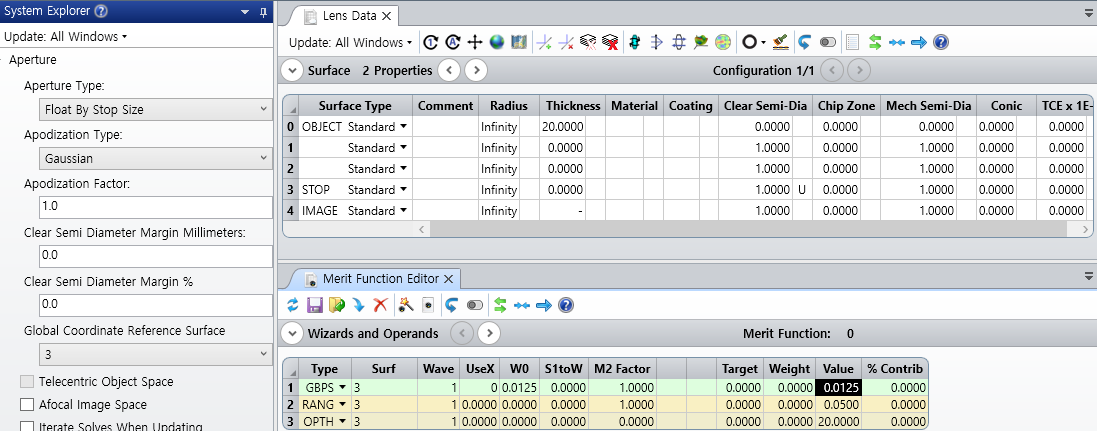

Case 2

- Surf #0 Thickness = 20

- Surf #1 Thickness = 0

- …

Analysis Type

- Operands

- RANG

- GBPS

- OPTH

- Tool

- Analyze...Gaussian Beam...Paraxial Gaussian Beam

- Stands Spot Diagram

As a result,

RANG, OPTH, and Standard Spot Diagrams have the same values for Cases 1 and 2.

However, the result values for GBPS and Paraxial Gaussian Beam are different.

So I wonder in which case to set Surf #0 Thickness = 0.. in which case to use Surf #0 Thickness <> 0. And I'm curious about the physical difference between the two cases.

Note that, I know that GBPS outputs beam size based on paraxial rays.