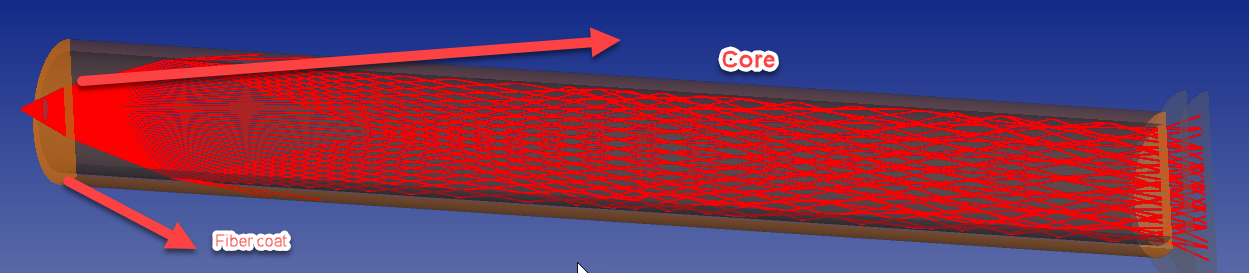

I'd like to model a step-index optical fiber (because I'm interested in modyfing it).

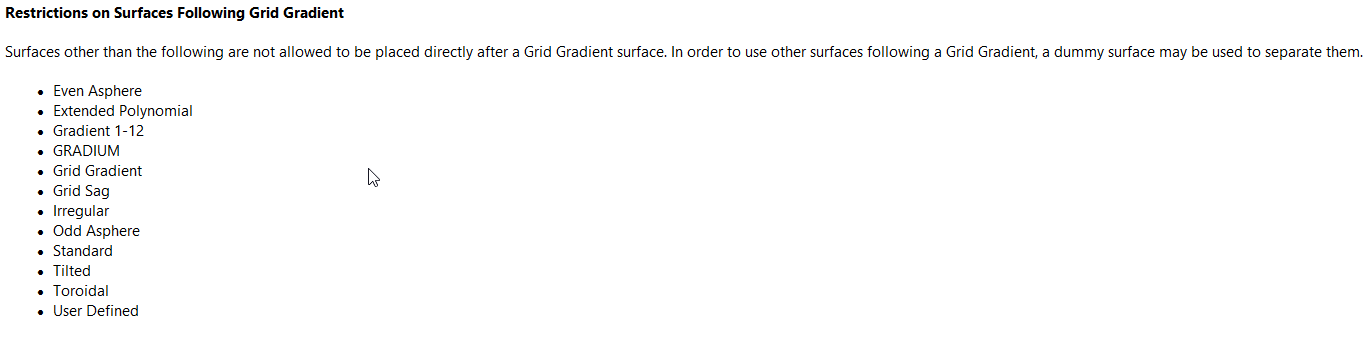

I tried to do that with a Grid Gradient with 1.55 - core index, 1.45 coat index, 4.6 um - core radius, 0.1 um - \Delta t

I created a Universal Plot with x - distance from the fiber face to the IMAGE surface, and y - FICL.

The problem is, the plot is almost identical with the fiber modeled as a Standard surface with 1.55 index, and both models change the FICL plot drastically when length of the fiber is changed.

I need to model fiber in such way, that changing length won't change simulation results.

1. Is it good idea to model step-index as Grid Gradient, or is there simpler way to do that?

2. Is FICL good enough to recognize the way light propagates through optical fiber or should I go for POP?

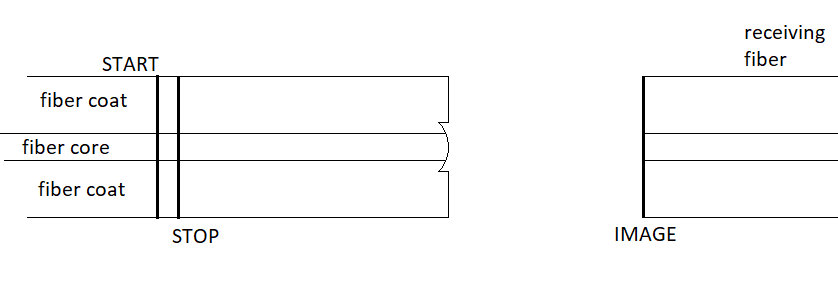

Also, I'd like to modify the fiber, firstly, by milling a lens in its face. I went for Standard surface with some radius. There are two problems:

3. The lens is created on top of the fiber face. Is there any simple way, to put it inside fiber?

4. Clear semi-diameter defines size of the lens, but it also blocks light propagating through no-lens surface. I'd like to simulate diffraction on the edge of the lens. Is there any simple way to that?

Below is a rough sketch of my model

Thanks in advance.