Hello,

Pretty new to this, and trying to design a lens package.

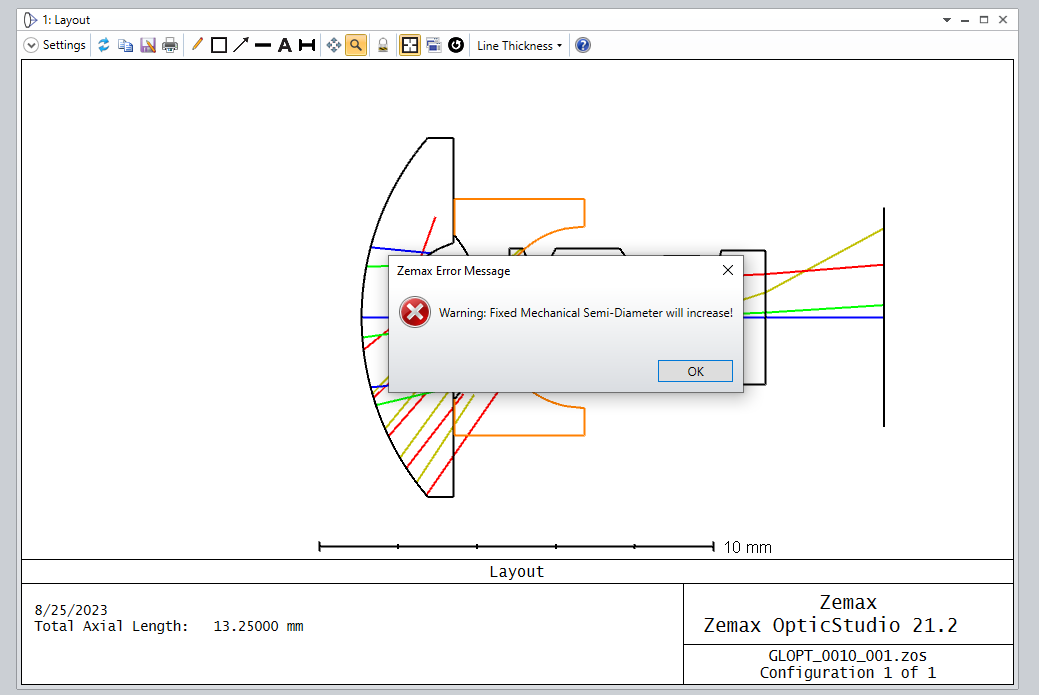

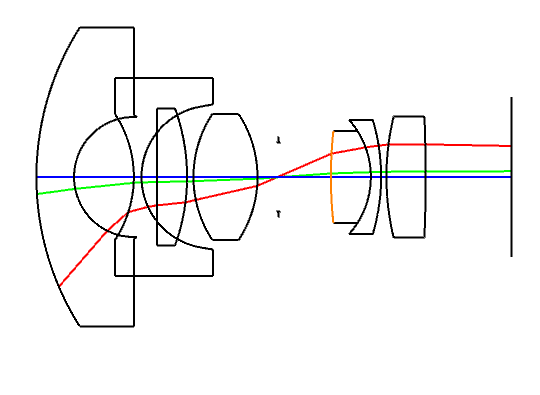

However, I have a problem with lenses overlapping when designing.

I like the radii to be the same, but I would like to “cut” the lens.

Changing the thickness won’t do it

Please advise.

Br, Oscar