Many off-axis mirrors are constructed using an off-axis aperture on a “parent” mirror. This can make tolerancing difficult, since the perturbations must be applied at the vertex of the off-axis aperture. Tolerancing can be easily and correctly set up using the Composite surface and Tilt/Decenter tool in OpticStudio, as shown below for an off-axis parabola (OAP).

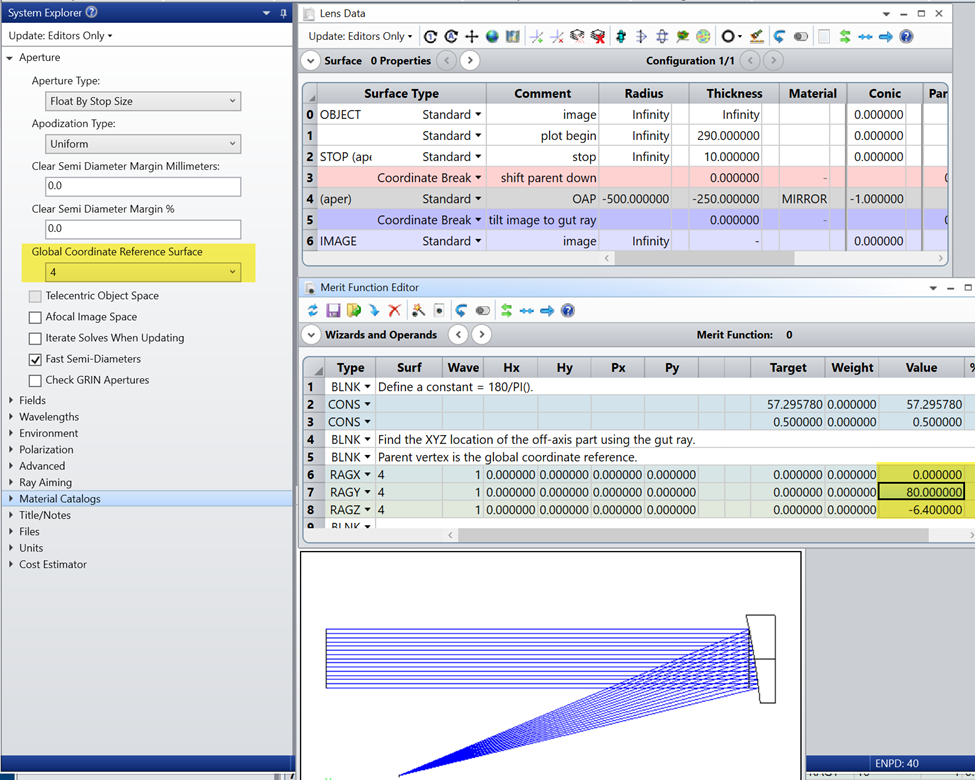

In this OAP file, the parent is shifted down from the stop so that the gut ray (at Px=Py=Hx=Hy=0) strikes the vertex of the off-axis mirror. We have set the global coordinate reference to the parent mirror, and used RAGX/Y/Z operands in the Merit Function to locate the vertex of the off-axis part.

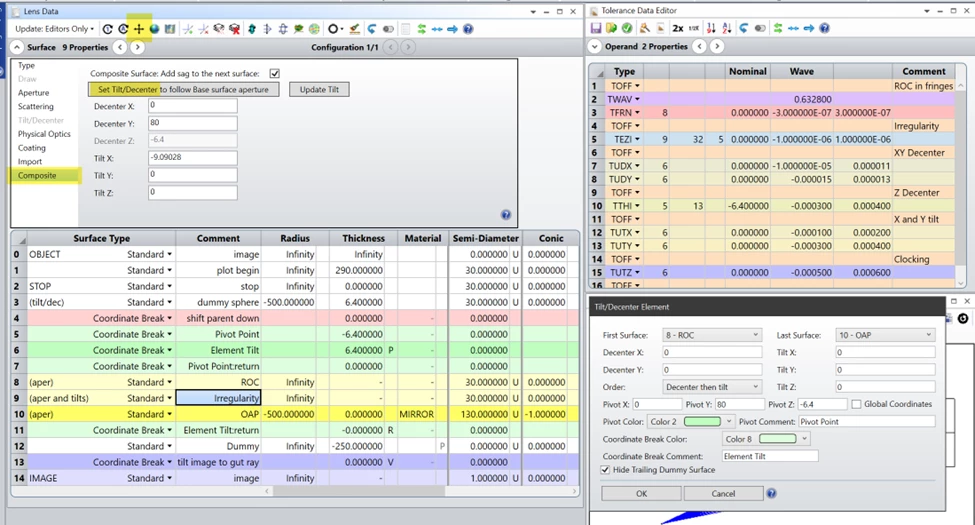

To prepare for tolerancing, we use the vertex coordinates to set up a pivot about the off-axis vertex, using the Tilt/Decenter Elements tool (located in the toolbar of the Lens Data Editor). We insert two Composite surfaces before the OAP, and use the Set Tilt/Decenter button to locate the two at the vertex of the off-axis mirror; the sag of these surfaces will be added to the OAP sag.

For tolerancing, a TFRN operand can be used to adjust the ROC of surface 8. TEZI is used to add irregularity to surface 9, starting at Zernike term 5 so that piston, tilt, and defocus terms are not added in the irregularity. TUDX/Y and TUTX/Y/Z operands control the decenters and tilts, found in surface 6. Z-decenter can be added using TTHI on surface 5.

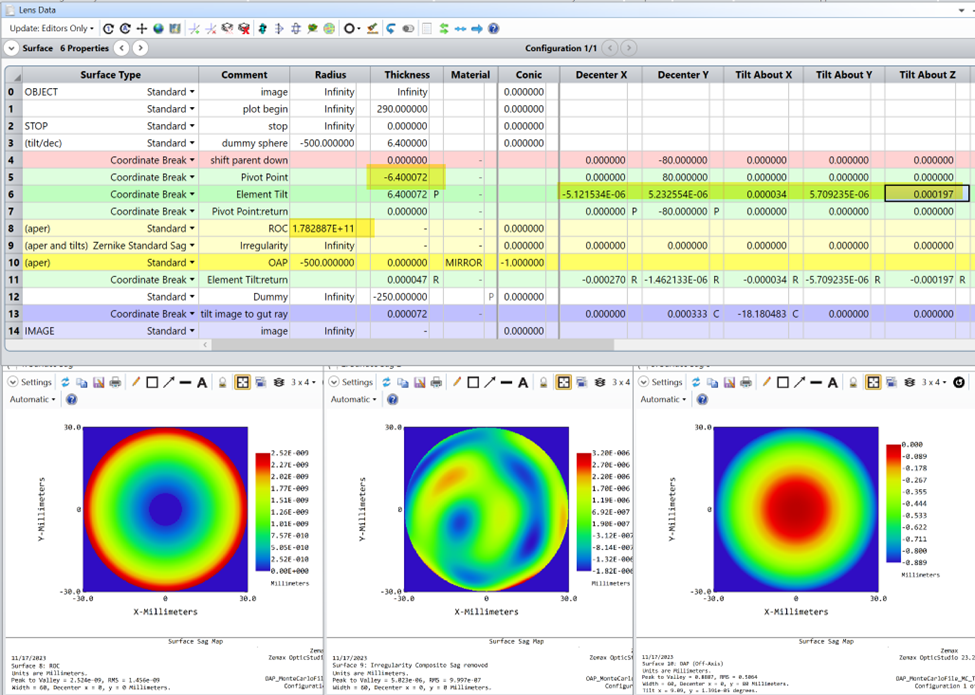

Saving a Monte Carlo file shows the changes that are made for tolerancing. Surface 9 is converted to a Zernike Standard Sag for adding irregularity. The ROC is adjusted on Surface 8. And tilts and decenter perturbations appear on surface 6. The Sag Maps can be used to observe the surface perturbations on surfaces 8, 9, and 10; the total sag of the surface (the sum of surfaces 8, 9, and 10) is held in surface 10.