Sorry that this title is not accurate. The TIR occurs sometimes when we recreate something from a patent or we add extra operands other than the operands generated by the field wizard.

I have been asked several times. I got this error message during my current project. So I want to share some thoughts about how to do this:

- Reduce the field/ numerical aperture to remove the TIR first

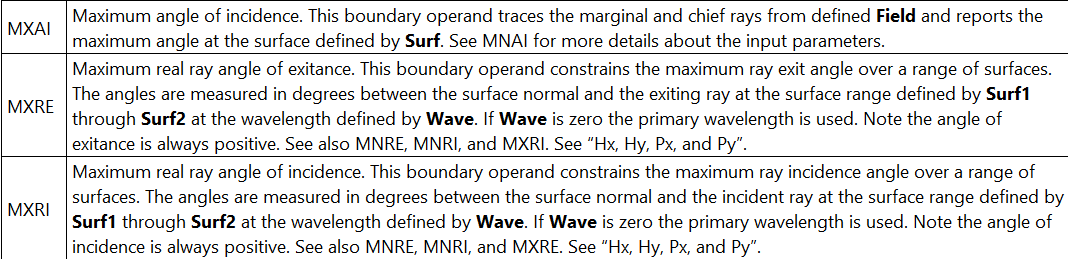

- Apply the RAID/ MXAI/MXRE/MXRI to constrain the incident angle

-

You can optimize the lens shape to reduce the angle

-

Try HYLD in optimization wizard Designing for as-built performance with High-Yield Optimization – Knowledgebase (zemax.com)