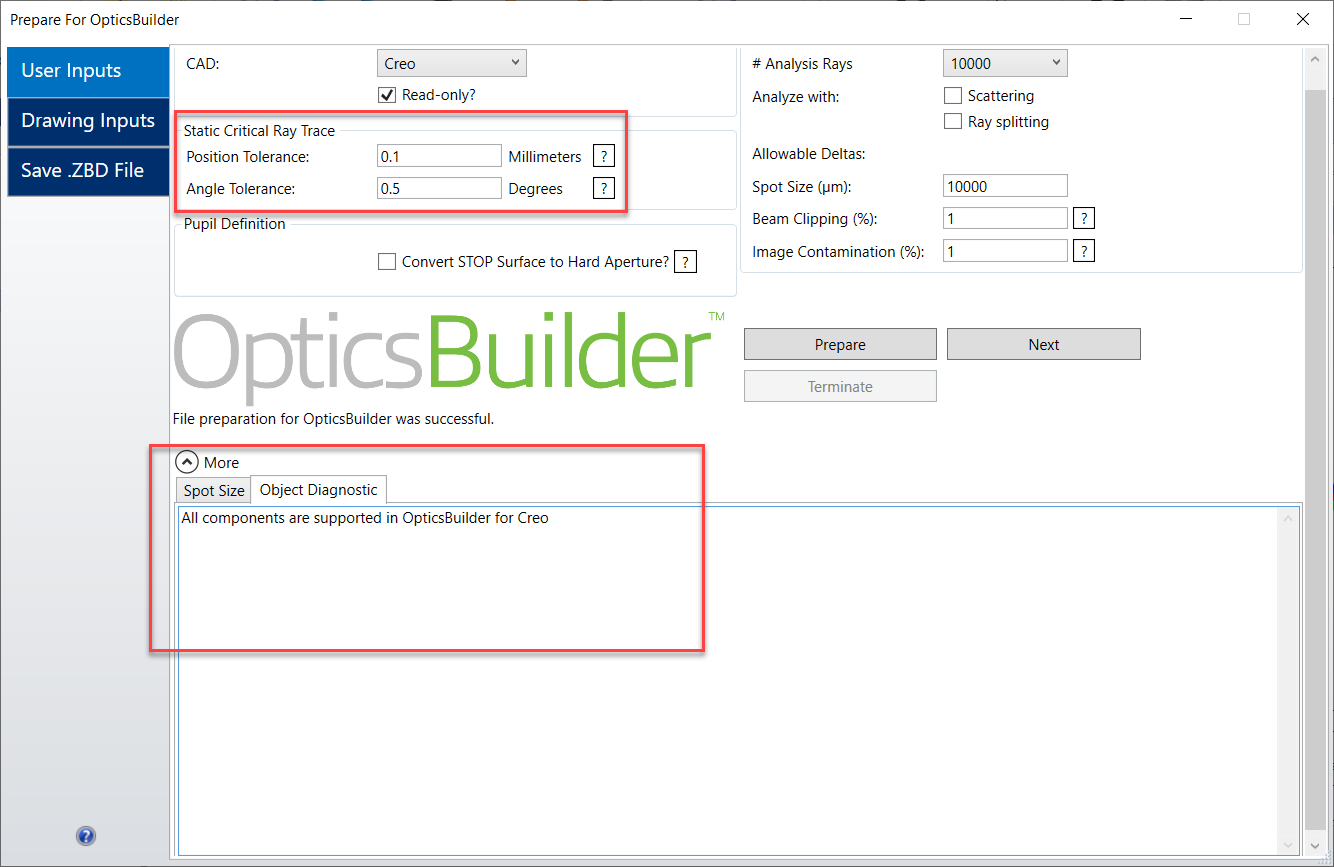

When using the Prepare for OpticsBuilder” tool you may choose the amount of allowable change in the location and angle of the critical rays. Position Tolerance represents the maximum allowed difference between a ray's landing position in the original file, and in the copied file. The Angle Tolerance will represent the maximum allowed angle between the target ray's vector, and the actual ray's vector. This tool helps engineers validate that conversion to non-sequential mode do not degrade the performance of the original sequential system.

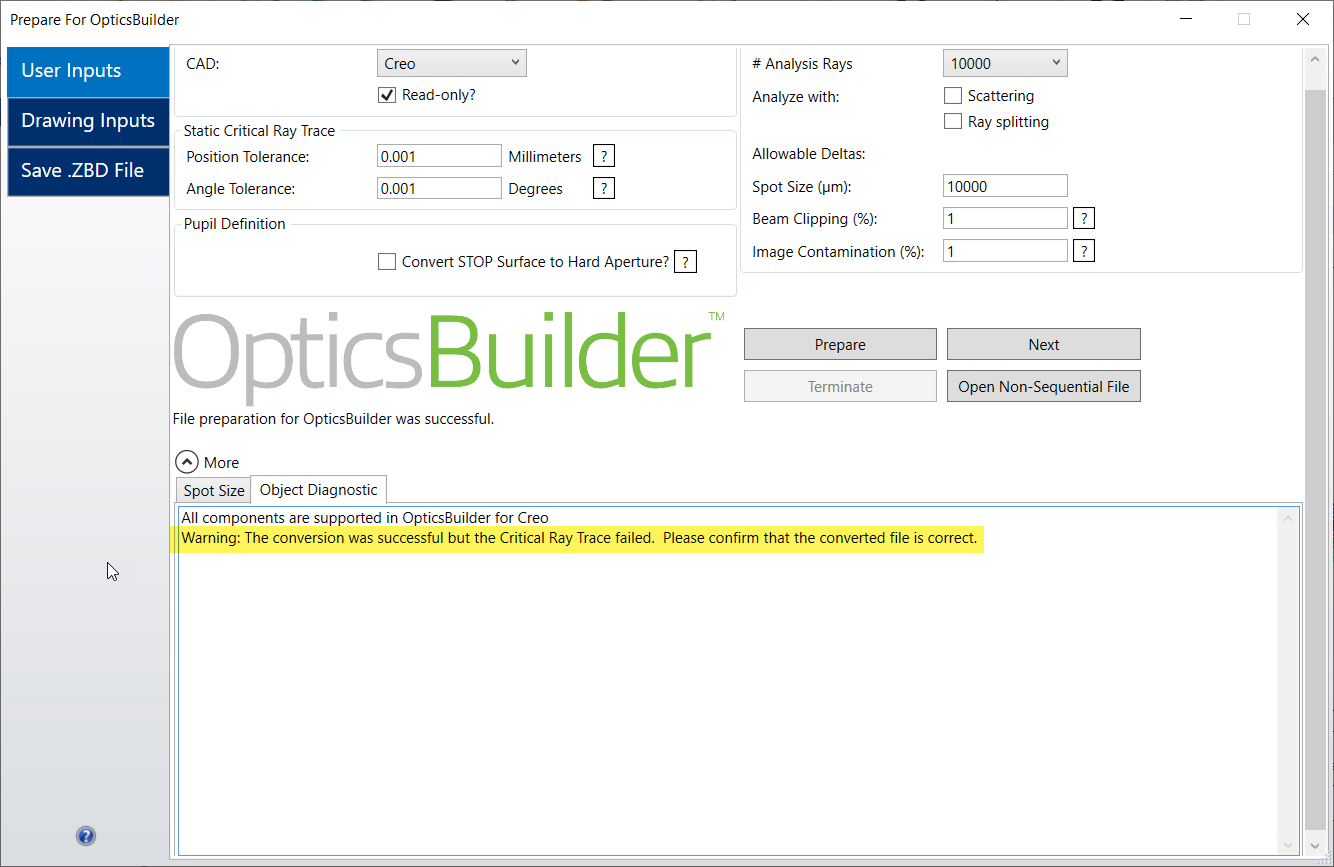

Sometimes due to differences in how rays are traced from Sequential to Non-Sequential Mode, the Critical Ray Tracer will fail even though the rays make it through the system. In this case, a warning comes up in the “Object Diagnostic” tab even though the file preparation is successful.

Actually, the “Critical Rayset Generator” is working fine. The failure comes within the Critical Rayset Tracer in Non-Sequential Mode. As for why it fails, it comes down to the position and angular tolerances we define. When we run the Critical Rayset Tracer, we see a long list of failed rays even though the rays are obviously making it through the system. So, we need to check out how different are the actual rays and the target rays. To do so, we can take that CRS file from the sequential file and check some of the rays in the Non-Sequential file (let’s say using a NSC single ray trace) to see how large are the discrepancies.

For longer systems like Riflescopes, the default Critical Ray Trace tolerances may be too small. That's why those tolerances are not that important to the conversion process. If we increase the tolerances, we get a passing score and the warning no longer shows up in “Object Diagnostic” tab.