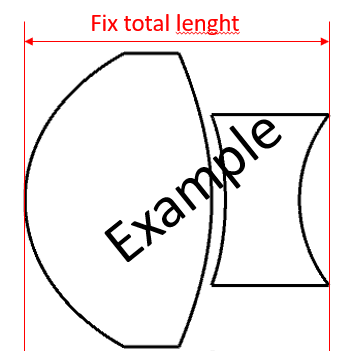

I want to limit total lens lenght in optimization and I want to do that for left-most point of the lens and right-most point of the lens, irrespective if this point is in the center, on the mechanical edge or even in between. TTHI only gives center thickness. XXET only reports edge thickness on mechanica diameter location. If lens size limitation is on the axis or on the edge only, that works OK. But if i.e. leftmost side is limited on the axis, and righmost side on the edge (concave shape), then also SAG of first and last lens need to be used. I have checked SAGY, but its Description in help is different then what is actual status in MF editor. There is no 'mode' possibility for SAGY and result is given for clear semi-diameter only, but I need mechanical semi-diameter. SSAG allows what I need, but Y (or X) coordinate should be input manually, which does not help me in optimization. I did not find a way how to get SAG value on mechanical semi-diameter automatically. I checked also other operands, but found no solution. I am sure there is solution, so I am grateful for your anwsers.