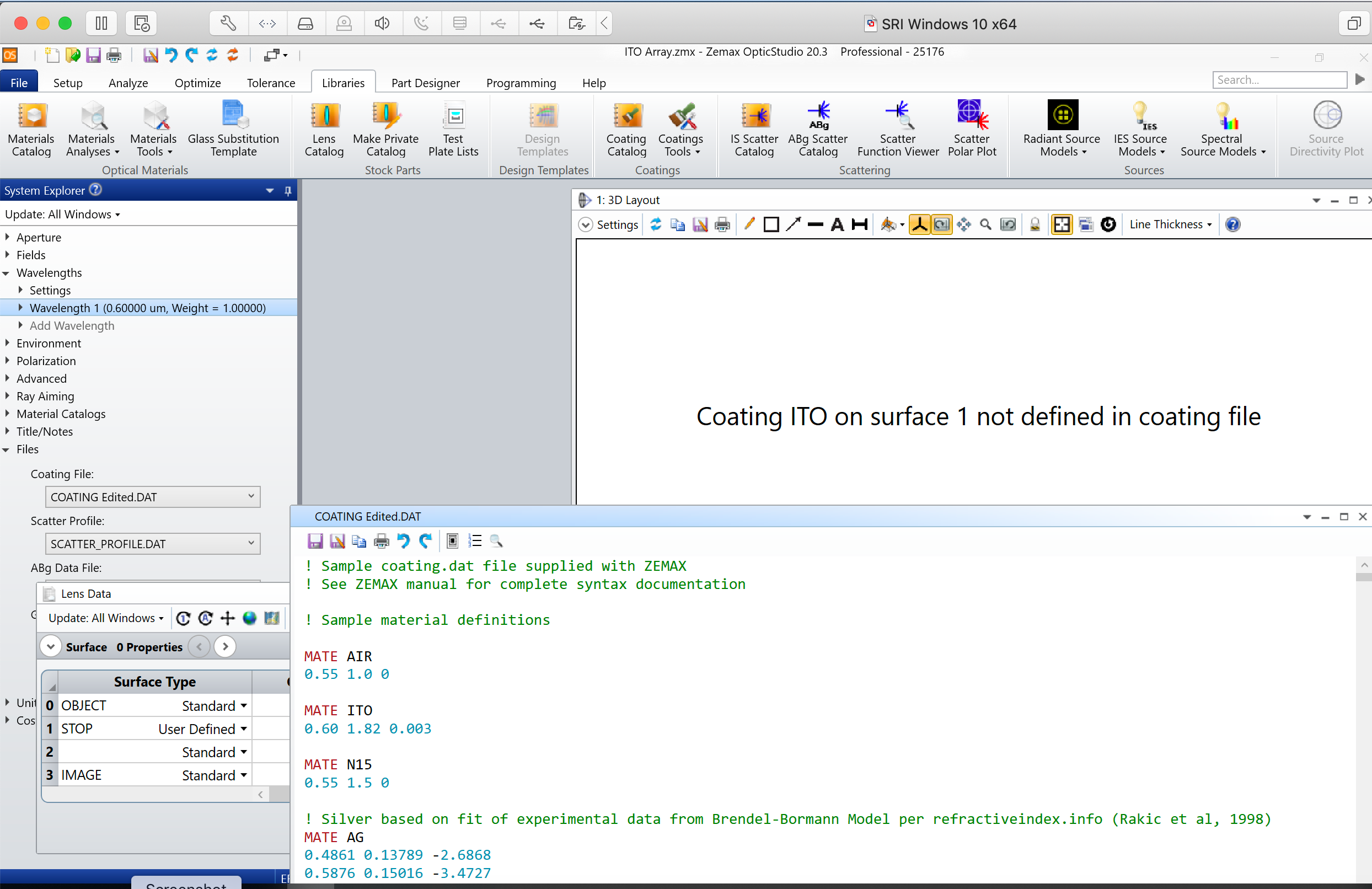

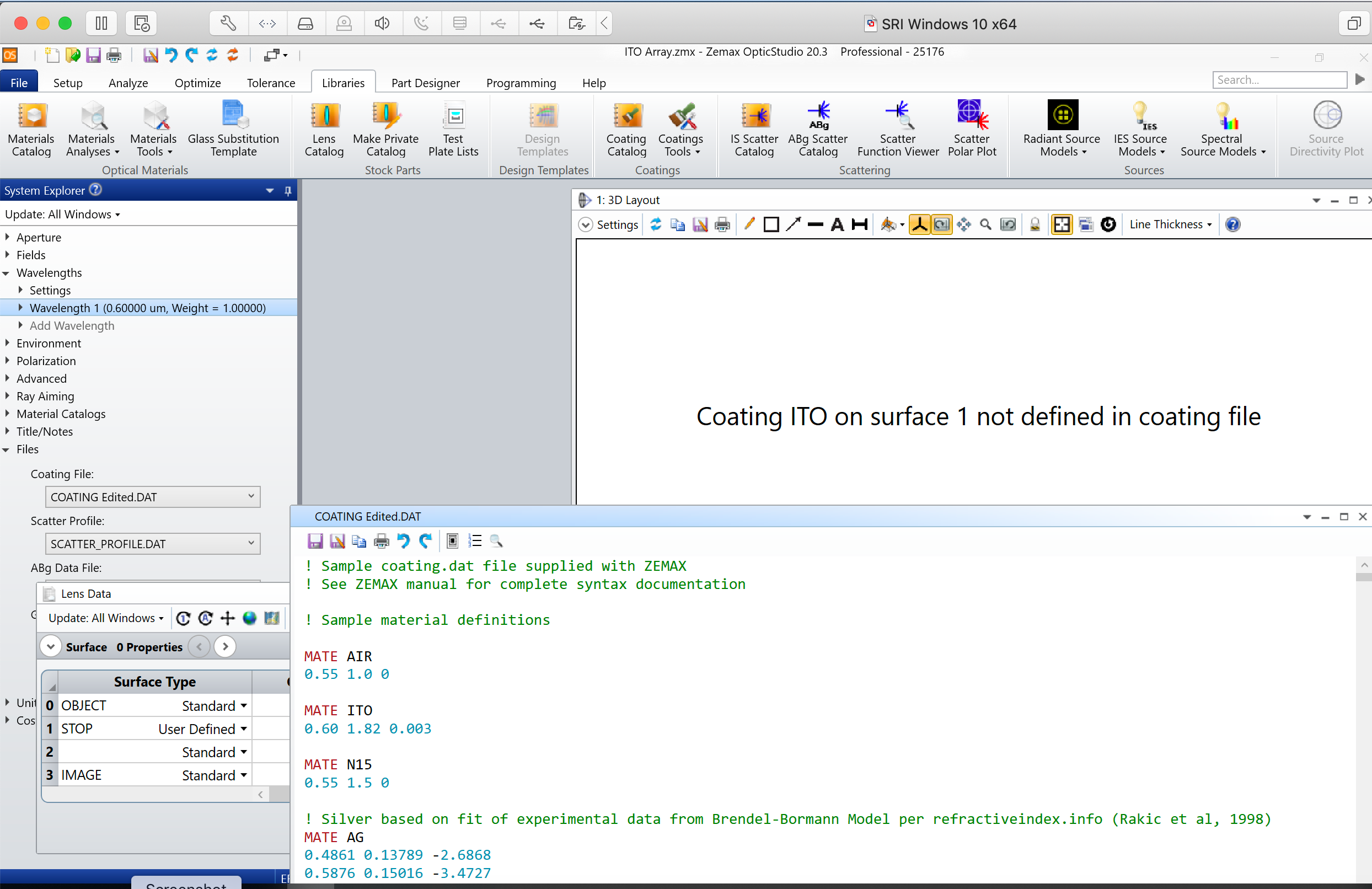

I tried adding a new coating to the coating library using your Coatings Tool, now the Coating Catalog is empty, and I can't display my lens design because I get the error message that the coating doesn't exist.

I tried adding a new coating to the coating library using your Coatings Tool, now the Coating Catalog is empty, and I can't display my lens design because I get the error message that the coating doesn't exist.

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.