Hello!

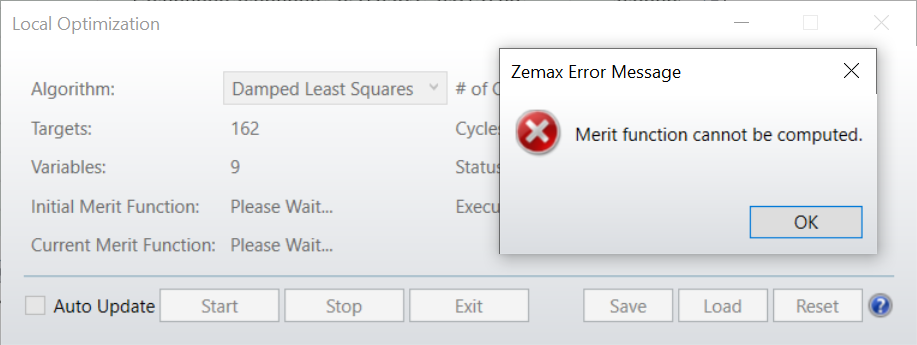

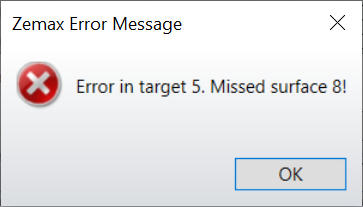

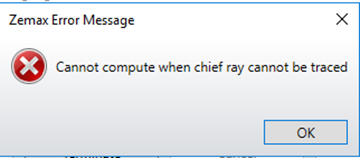

I keep getting the error message:

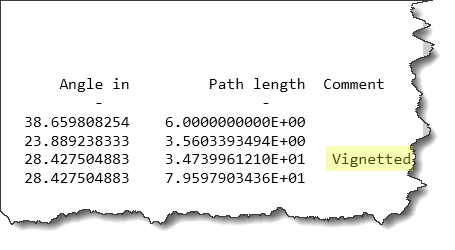

'Cannot compute when chief ray cannot be traced!'

during optimization using least squares method. The optimization interrupts and resumes once I click 'ok' or 'X' on the message pop-up window.

- Any ideas how I could interrupt at the point where the error-message pops up to investigate the cause?

- Are there any options to automatically ignore this message and resume the optimization without having to click the message away manually?

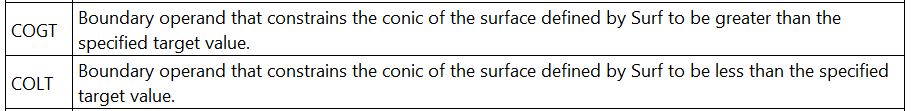

I am using the damped least squares optimization to optimize the shape of the example UD surface 'us_multizone_asphere' with two zones. I already tried different merit function operands without success. As it did not occur with simpler surface structures, I assume that some geometric surface constraints are required.

- Any ideas how to approach this (e.g. setting appropiate geometry constraints...)?

Thank you!

Simon