I’m modelling a double-pass system, which can be simplified to the Knowledgebase help tutorial at this link. The tutorial only covers element tolerances, but I’m interested in modelling surface tolerances. In particular, the Surface Irregularity tolerance - I see no way to have ZEMAX “pick up” the same random perturbation onto the surface from the first pass onto the second pass of that surface. Similarly, I suspect TIND (index tolerance) is also applied separately despite double pass.

For decenter and tilt, I’ve figured out this can be approximated by “lumping together” the element and surface tolerances together. If there are two 0.1mm decenter tolerances, one on the lens surface, and on on the alignment of the lens, then the combined tolerance is 0.1*sqrt(2) mm.

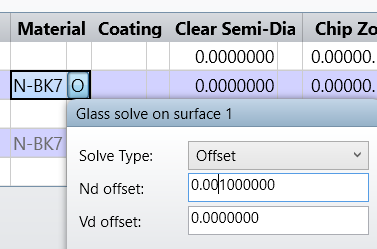

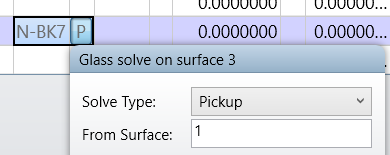

What would you suggest I do for the TEZI/ TIND tolerances?