Topic: Selecting a laser propagation method in OpticStudio

Live solution reveal and Q&A: July 20th, 8am - 9am PDT (See the attachments for a calendar invite)

Engineer:

Ask an Engineer is LIVE again this month! Try out the challenge below to learn more modelling laser beams in OpticStudio, then come back on July 20th to discuss. Submit your solution or questions as a reply to this thread.

Challenge opens: July 7th

Submit your file as a reply by: July 19th, EOD

Live event: July 20th 8am PST (the calendar invite is in the attachments)

Challenge:

OpticStudio supports several different approaches to model a laser input for your system. They include:

- Defining your geometric ray bundle with the correct aperture apodization and divergence angle

- Utilizing the Paraxial Gaussian Beam or Skew Gaussian Beam analysis to define and propagate your laser beam

- Generating and analyze your laser beam using the Physical Optics Propagation analysis

Each approach bears their own benefits and limitations.

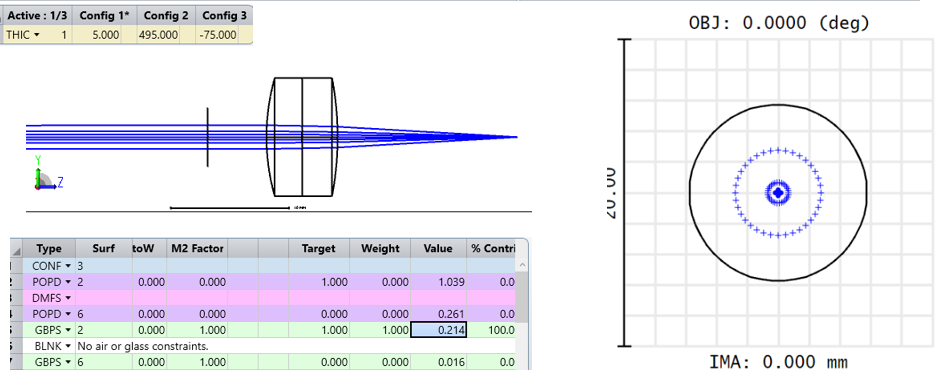

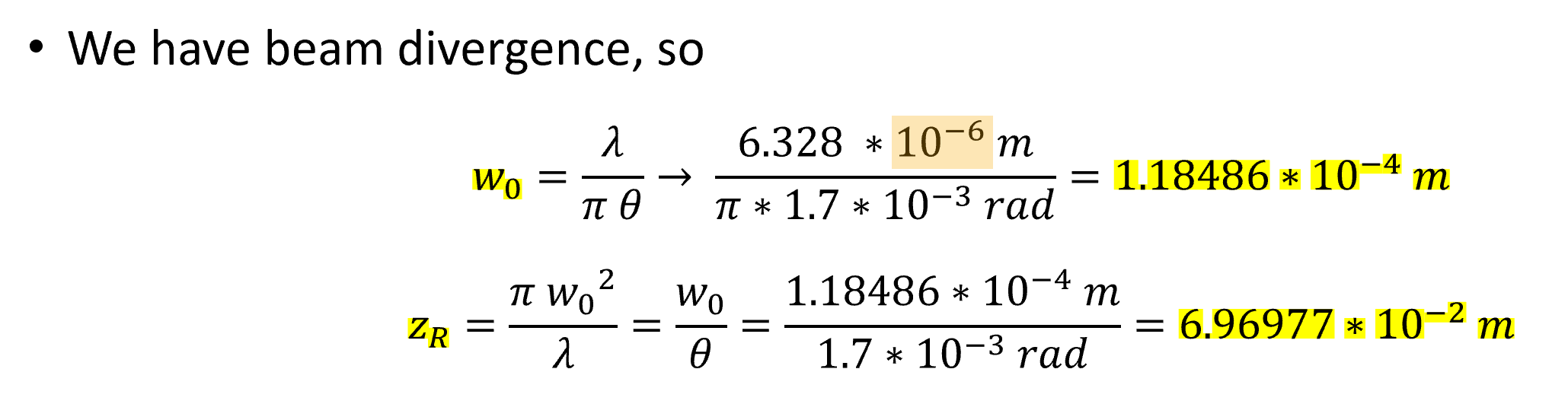

For this month’s challenge, participants are asked to define a laser beam in OpticStudio and propagate it through a doublet. The laser beam we will be using is provided in the following product specification: 0.8mW 110V Random, HeNe Laser | Edmund Optics. The doublet is provided as an attachment, and it is a slightly-modified version of our Doublet sample file.

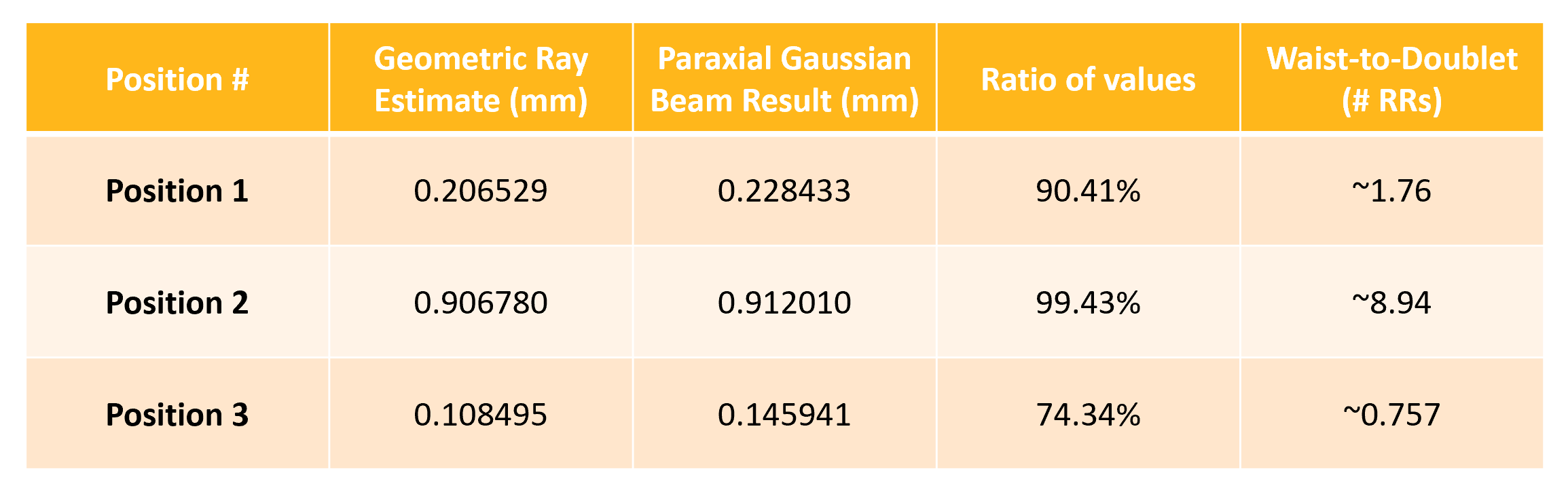

Assume the measured beam diameter from the product specification is exactly at the exit port of the supplied laser. Participants are asked to obtain a beam size value for three different positions of the doublet relative to the exit port:

- Position 1: Doublet’s first surface vertex co-located with the exit port of the laser

- Position 2: Doublet’s first surface vertex located 500mm to the right (+Z direction) of the exit port of the laser

- Position 3: Doublet’s first surface vertex located 70mm to the left (-Z direction) of the exit port of the laser (a bit unphysical, but this is a challenge!)

For each position of the doublet, sample the beam size at an image plane 15mm after the last surface of the doublet. Participants should decide which of the above approaches for modeling laser input are suitable.

Files:

- A slightly modified version of the default Doublet.ZMX/.ZOS sample file (the only change has been removal of variables and Marginal Ray Angle/Height solves)

- A calendar invite for July 20th. This will connect you to the Teams meeting where Angel will present his solution and answer questions.

Resources/Tips:

- There are multiple solutions for this type of system setup. We encourage you to discuss and post your questions in the thread below.

- Different laser modelling approaches may be required for each position of the doublet. Carefully consider whether the data you’re seeing makes sense.

- Note: This is an important skill in simulation! Knowing what to expect helps us to avoid errors in the simulation setup.

- If you need a bit of a push for a starting point, take a look at our Part 1 article for How to model laser beam propagation in OpticStudio. You may find a bit of inspiration…

Questions? Comments? Ready to submit your file? Reply to this thread. Replies may be posted in any supported language (English, Chinese, Japanese). Once the event is concluded, the thread will be closed.

The Ask an Engineer live event will be limited to discussing this challenge and general questions related to the topic. For questions on troubleshooting personal OpticStudio files, please submit a ticket with Zemax Support. In that case, your license support status will be considered.