This thread will be used to collect questions before the webinar, and to answer any questions we received during the webinar. Feel free to post your questions!

Be sure to subscribe to this thread if you want to see additional discussion regarding this topic. The thread will be open to comments through Friday, May 27th.

[The event has concluded]

Date: Thursday, May 19th

Time: 6:00am PST & 11:00am PST

Presenters:

- Shin-Sung Kim, Manager Application Engineering

- Csilla Timar-Fulep, Senior Application Engineer

Abstract:

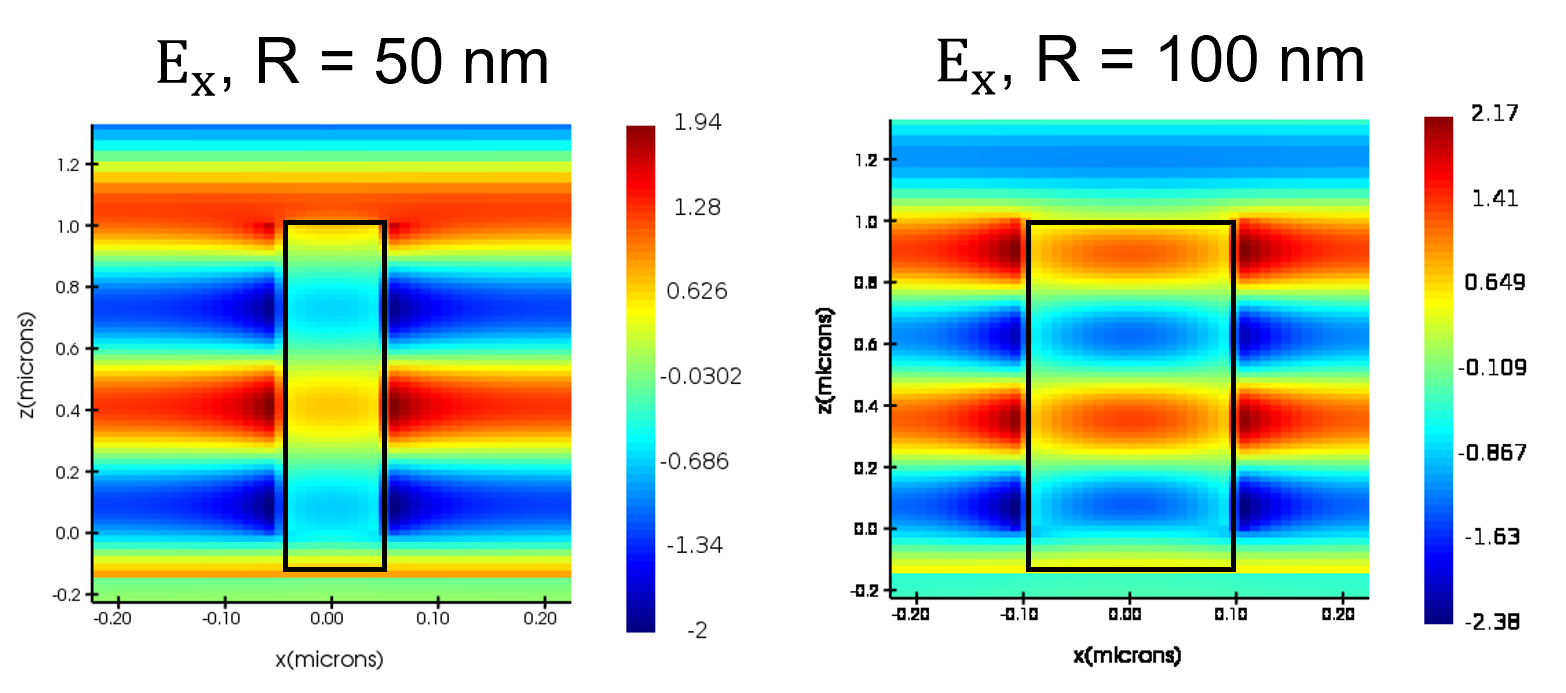

In this webinar, we will examine how the portfolio of Ansys Optics tools offers a complete workflow for the design of metasurfaces, or metalenses. These revolutionary ultra-thin optical components can be used to manipulate light in the visible and IR range for many applications, including smartphone cameras, AR/MR displays, 3D sensing and face recognition. Because of the sub-wavelength nature of metasurfaces, it is critical to use a combination of electromagnetic field solvers (Ansys Lumerical FDTD/RCWA) to accurately determine the phase and field profile of the metalens and ray tracing (Zemax OpticStudio) to optimize the desired lens properties.