This thread is dedicated to the webinar: OpticStudio-OpticsBuilder-OpticStudio STAR Module Interoperability in Design of High-Power Laser Systems. Any questions received during the webinar will be responded to as a reply on this thread. Feel free to post your own questions! The speaker will be notified and will respond as long as the thread is still open.

Be sure to subscribe to this thread if you want to see additional discussion regarding this webinar topic. The thread will be open to new replies through Friday, July 8th.

[The webinar has concluded]

Webinar details

Date: Tuesday, June 28th

Presenter: Mojtaba Falahati, Senior Application Engineer at Ansys Zemax

Abstract:

Join Mojtaba Falahati, Senior Application Engineer, as he explores the optical-optomechanical design cycle for high-power laser systems using a typical example and describes how Zemax tools enable a joined-up workflow to turn optical designs into reality. High-power laser systems are extensively used for high-precision cutting, welding, etching metals and other materials requiring a seamless design.

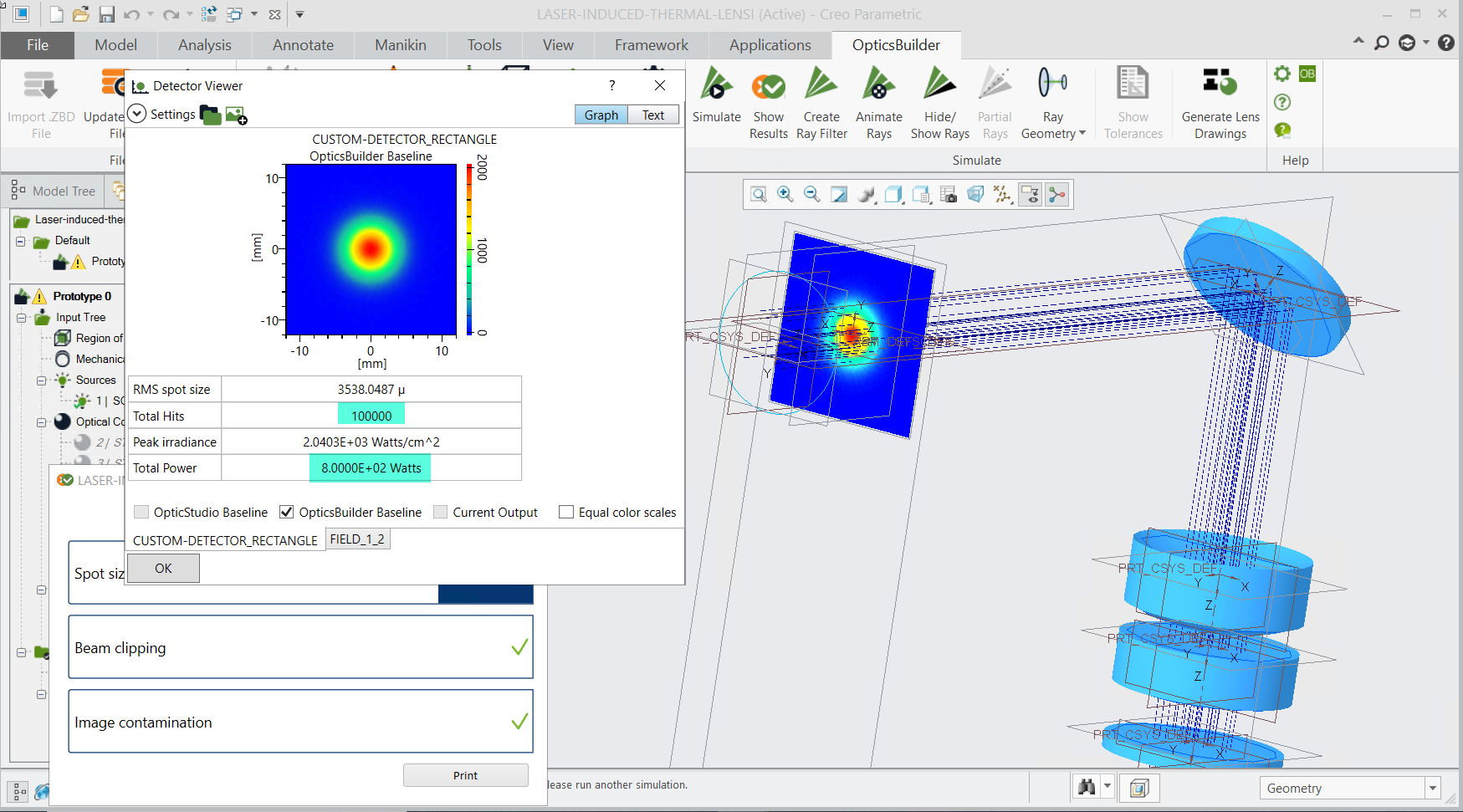

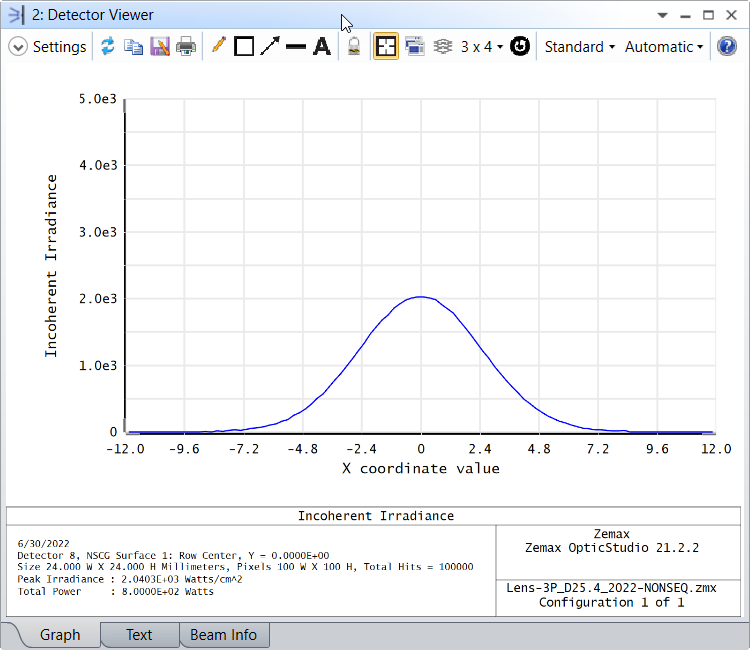

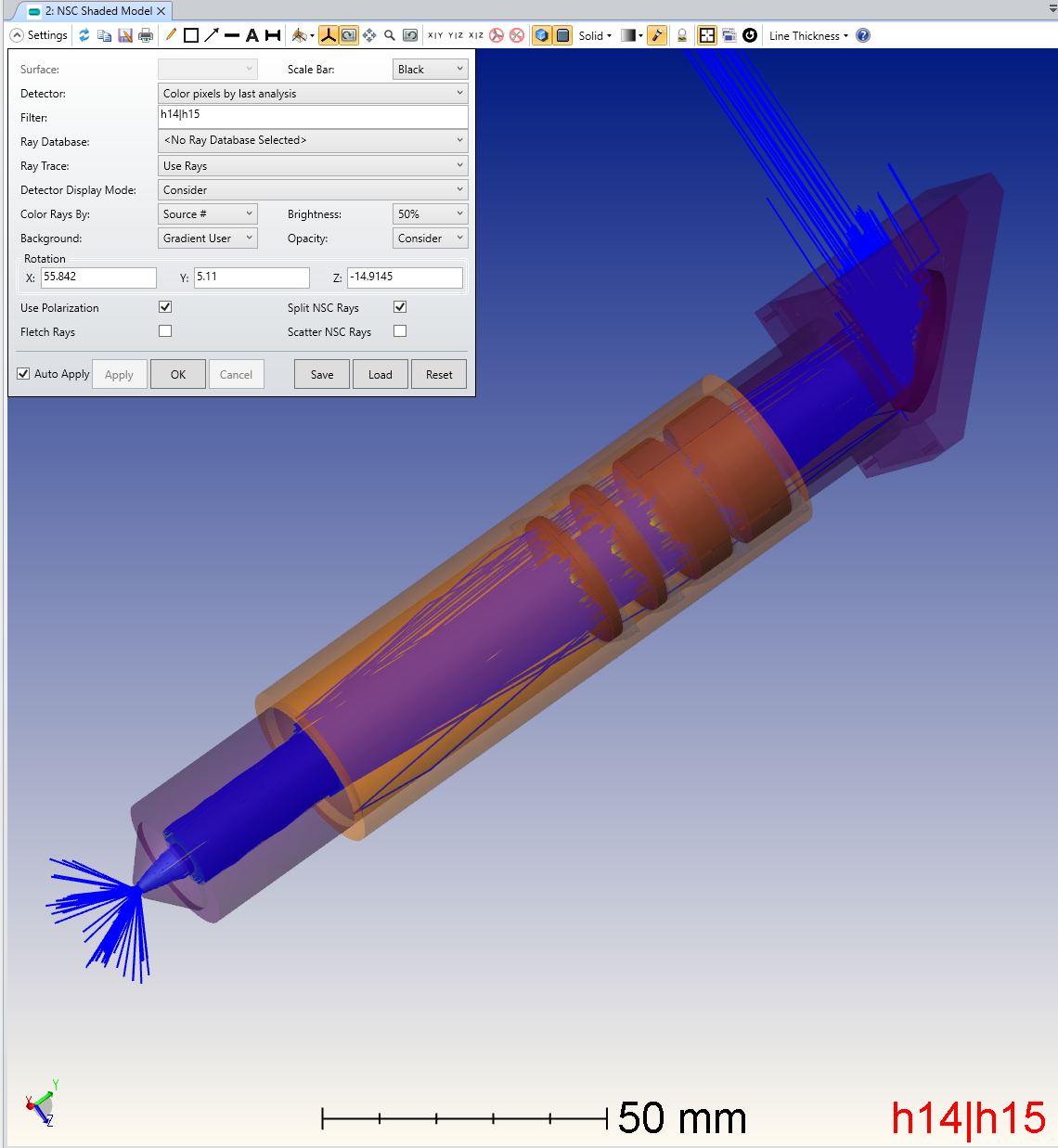

Laser beam and the desired optical performance can be well modelled in OpticStudio and converted to a CAD friendly format. Mechanical packaging can be efficiently designed in OpticsBuilder while accessing the live optics model, and STAR enables FEA data import for STOP analysis. The interoperability between OpticStudio, OpticsBuilder and STAR streamlines the design process by:

- Effective communication between optical and mechanical designers as they navigate the design changes.

- Real-time visualization of impact on optical performance while designing optomechanics.

- Detecting costly errors early in the design process.

- Hassle-free export to OpticStudio for advanced analysis.

- Integration with FEA packages to perform detailed impact assessment of structural and thermal effects on optical performance.