This thread is dedicated to the webinar: Cell Phone Lens: The Fundamentals Behind the Optical System Design. Any questions received during the webinar will be responded to as a reply on this thread. Feel free to post your own questions! The speaker will be notified and will respond as long as the thread is still open.

Be sure to subscribe to this thread if you want to see additional discussion regarding this webinar topic. The thread will be open to new replies for a limited time following the event.

This event has closed. Click here to watch the recording.

Presenter: Katsumoto Ikeda, Manager Application Engineering

Abstract:

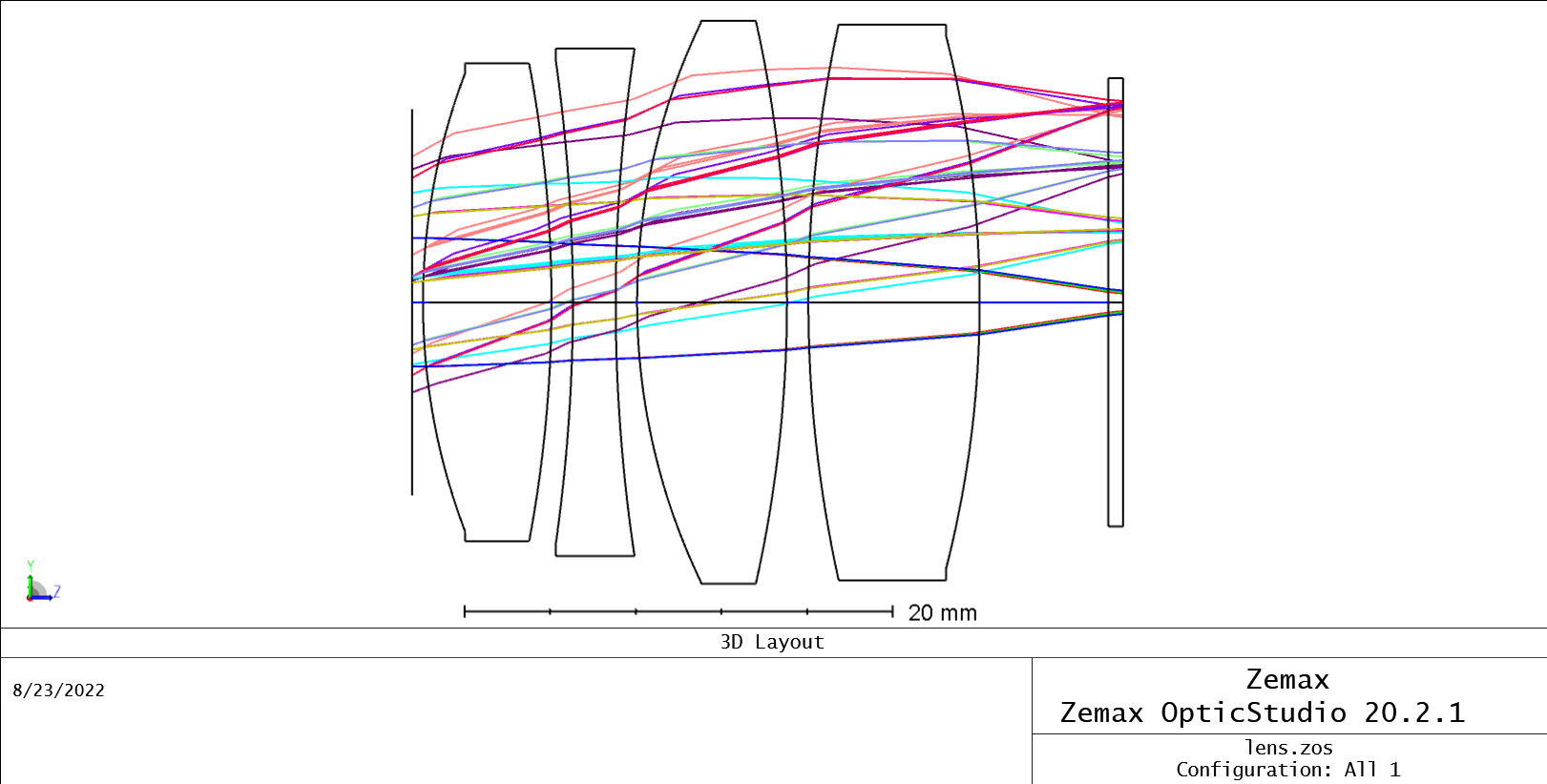

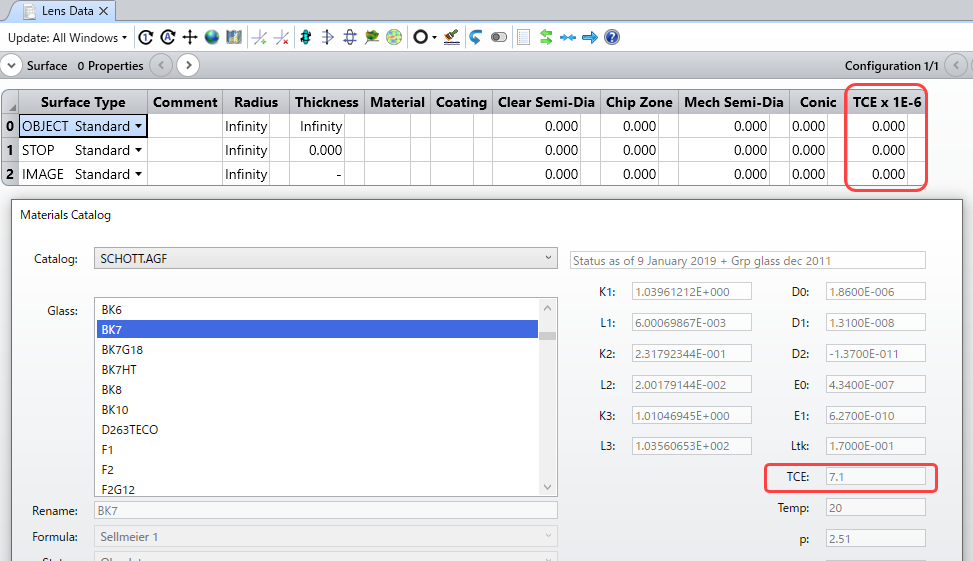

The methods and tools for optical lens design have been evolving for over a hundred years, and today we have modern computing software to assist our lens design process. In particular, the degrees of freedom that plastic lenses provide, coupled with the computational power of today's computers with software have made the optical lens design of plastic optics more advanced than ever before. One example of a complex optical design using plastic optics is the mobile phone lens. The design process of a modern mobile phone lens used in smartphones is our topic for this presentation. We will break down the optical lens design process and identify the characteristics of a typical mobile phone lens. We will investigate various procedures of the lens design process. We start with the concept of a cell phone design, what is important and how to optimize from an optical point of view.

Following the optical design, we will investigate the mechanical design particular to cellphone designs, and also add the housing of the cellphone lens, to ready the design for production via optical simulation with mechanical parts. Finally, we will start to consider the thermal and structural effects of the lens to analyze environmental factors. The entire process will be a guide to virtual prototyping of optical lens design so that we can effectively ready our lens design into production quickly and more efficiently.