I want to share this because I wasnt able to find any information on it in my original searches and the help is a little confusing on the requirements. I’ll use the PT (polynomial) taper as an example since its what I used.

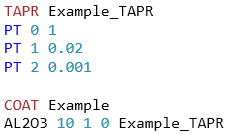

To start with, an important element to remember is that anything in the coating has to come before it in the coating.dat file-so both the TAPR and the MATE have to be before the COAT to function properly.

For each PT line, the first element is the order (x^2, x^1, etc) and the second the coefficient. As such, order zero defaults to 1, so it can be excluded here, but knowing its one is important for understanding how to generate coefficients. My initial error was that the coefficients (C2, C1, C0) where as follows, with a thickness d and a position x (in this case, looking at a single axis):

C2*x^2 +C1*x +C0=d(x)

However, this is inexact. For TAPR coefficient (g2, g1, g0) its more accurately the following:

d(0) * (g2*x^2 + g1*x+g0)=d(x)

To compare with the previous formulation:

g2=C2/C0=0.001, g1=C1/C0=0.02, g0=1, d(0)=10

Hopefully this can save someone else the time it took me to figure this out.