March 22nd, 2023

1 Tools, Features, and Capabilities

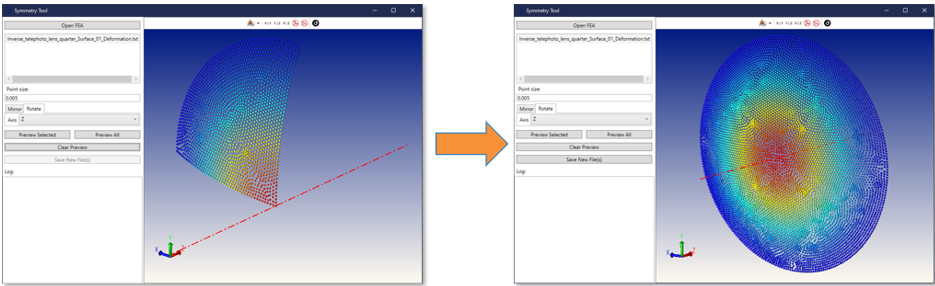

1.1 STAR: FEA Symmetry Tool (Enterprise Edition)

Speed up the entire STOP workflow by taking advantage of symmetrical assumptions.

Ansys Zemax OpticStudio Enterprise now enables you to utilize FEA datasets from simulations that take advantage of symmetrical assumptions. Full FEA simulation models often have extended run times that can go from several hours to several days. This means that for an FEA engineer to share FEA datasets with optical engineers, it requires a large undertaking which is especially difficult for an iterative design workflow. FEA engineers can use symmetrical assumptions in their models to reduce the overall run time and results in less time for the simulation to converge. However, to utilize STAR tools in OpticStudio Enterprise, the FEA datasets need to cover the entire aperture. To support this workflow, the FEA Symmetry tool enables optical engineers to take ”partial” FEA datasets and use mirror or rotational tools to create new FEA datasets that cover the entire optical aperture. These new FEA datasets can then be loaded into OpticStudio via the STAR Load FEA Data tool.

The FEA Symmetry tool works with structural and thermal FEA datasets and enables users to save multiple files at once. The result is significantly less time in between STOP analysis iterations and, in the process, overall. Note that not all FEA simulations feature symmetrical loads that can be accurately modelled with symmetrical assumptions.

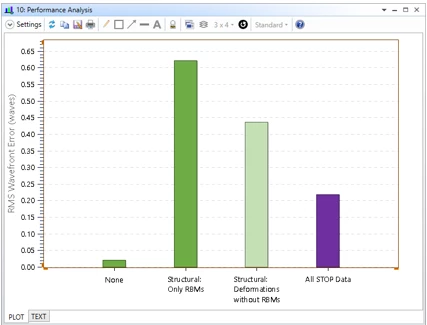

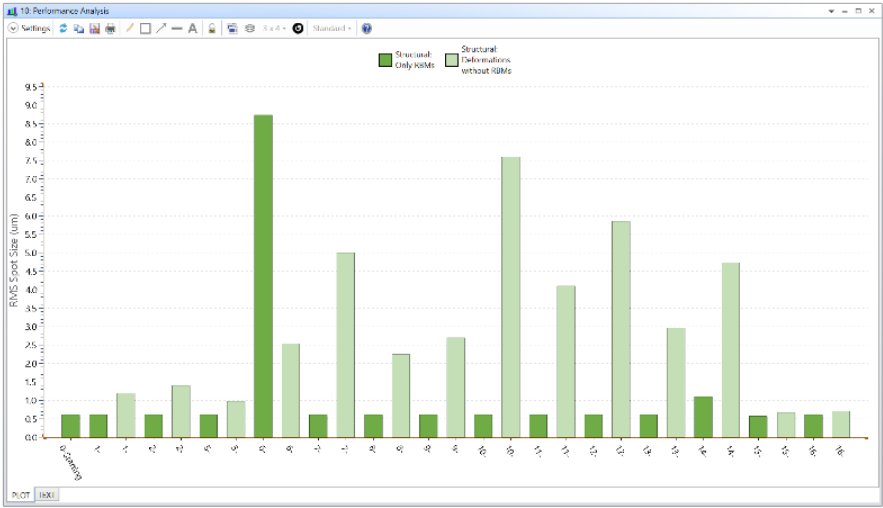

1.2 STAR: RBMs in Performance Analysis (Enterprise Edition)

Easily quantify the effects of RBMs and surface deformations independently.

The Performance Analysis has a new setting that will display information about the effects from the rigid-body motions (RBMs) separately from the surface deformations. These additional bars in the Performance Analysis bar chart provide you a more granular view into what is affecting the optical performance of your system - giving insights into whether you should focus on how the components are moving or how the surfaces are changing. With the more detailed “Show Errors for Surface” setting, the Performance Analysis can even show this data on a surface-by-surface basis, thus helping you to isolate the worst offenders in your system - simply with a click of a button.

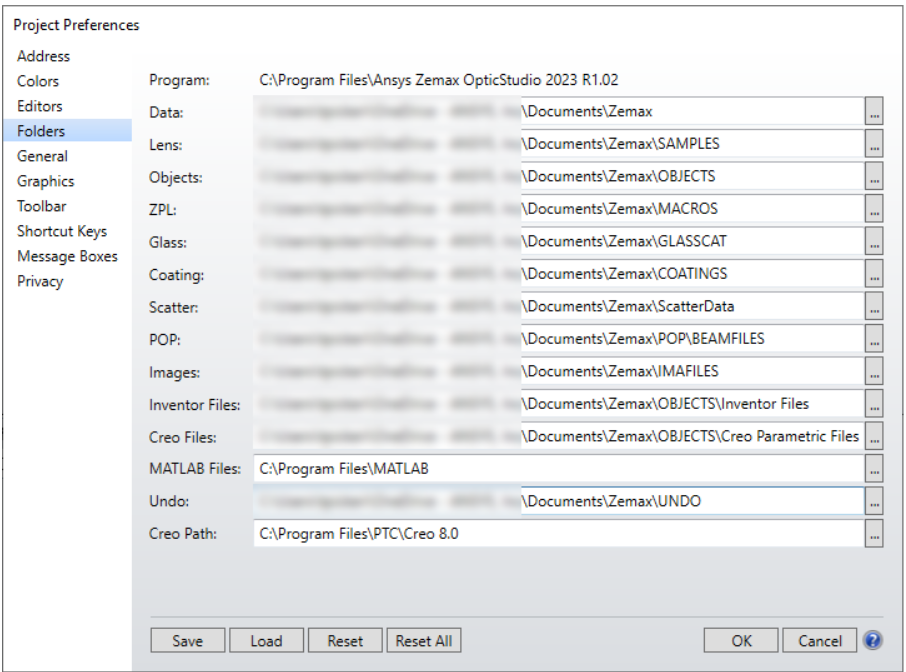

1.3 Creo 8 Dynamic Link Support (Premium and Enterprise Editions)

Dynamically modify and optimize parts and assemblies created with PTC Creo Parametric 8.

With OpticStudio Premium and Enterprise you can dynamically open PTC Creo Parametric part and assembly files in Non-Sequential Mode in order to model and parametrically control objects that aren't easily modelled by primitive or common shapes. The native CAD part is easily incorporated into the Non-Sequential Component Editor using the associated object type. Any explicit dimensions defined on the object can be exposed and controlled within the Non-Sequential Component Editor. This will allow optical engineers to be able to work with the same files that their mechanical engineers use, without the need for format conversion.

OpticStudio now supports dynamic links to PTC Creo Parametric 8, as well as to the following legacy releases of the software: Creo Parametric 7, 6, 5, and 4. To modify the Creo version to be used, simply set the path to your preferred Creo installation in the OpticStudio Preferences.

2 Performance and Stability Improvements

- Diffraction DLL: lumerical-sub-wavelength-2023R1-2.dll – An improved error logging was added to enable users to check for any issue in the JSON file format. Users can now set the DLL parameter "Test Mode" to 1 to save a log file in the \Document\Zemax\DLL\Diffractive\ folder where any loading error will be reported.

3 Libraries and Catalogs

3.1 Catalog Updates (All Editions)

Get the latest material catalogs from Micro Resist Technology and Qioptic Photonics.

Materials

-

The Micro Resist Technology (MRT) lens catalog has been added:

-

New catalog with 7 materials: ORMOCLAD, ORMOCLEAR®, ORMOCLEAR®30, ORMOCLEAR®FX, ORMOCOMP®, ORMOCORE, ORMOSTAMP®

-

MRT’s “Ormo” product line comprises organic-anorganic hybrid polymers made for optical applications. They combine high transparency from the visible down to the NIR region with extraordinary stability compared to purely organic polymeric materials. Hybrid polymers are UV-curable requiring only low processing temperatures and short production times. The products in the catalogue cover different refractive indices and process compatibility.

-

Test Plates

-

The Qioptiq Photonics test plate list has been added:

- New Test Plate list with 1451 test plates.

- This test plate list replaces LINOS Photonics test plate list in previous releases.

4 Bug Fixes

- Diffraction DLL: lumerical-sub-wavelength_dynamic_link-2023R1-2.dll – Fixed an issue in the DLL, where the phase of a diffracted ray was calculated incorrectly when performing coherent analyses, such as the Huygens PSF. Please note, the lumerical-sub-wavelength-dynamic-link-2023R1-2.dll version should only be used with Lumerical FDTD 2023 R1.02. Similarly, previous versions of the DLL cannot be used with Lumerical 2023 R1.02.

- Ray Aiming – Fixed an issue with the ZOS-API where applying the recommended ray aiming settings in the System Explorer were different from the settings from GetRecommendedSetting.

- NSC Sag – Fixed an issue in the NSC Sag analysis where OpticStudio would sometimes crash when tilts were applied to an object.

- Optically Fabricated Hologram – Fixed an issue where Optically Fabricated Holograms would not recognize the construction file references after being extracted from ZAR.

- User Defined Object – Fixed an issue where the side face of a User Defined Object with the DiffractionGrating object DLL was incorrectly defined.

- STAR – Fixed an issue in which the STAR ray trace solver would choose the unexpected intercept point when a surface had more than one potential surface intercept.