Hello Zemax Community!

I have been looking at the tolerancing for an achromatic doublet design, and had a question regarding the positioning of the elements post-tolerancing. In some cases, the front surface of the 2nd element of the lens will move in front of the back surface of the second element of the lens. Is there a way to control thicknesses such that the doublet surfaces are physically in sequence?

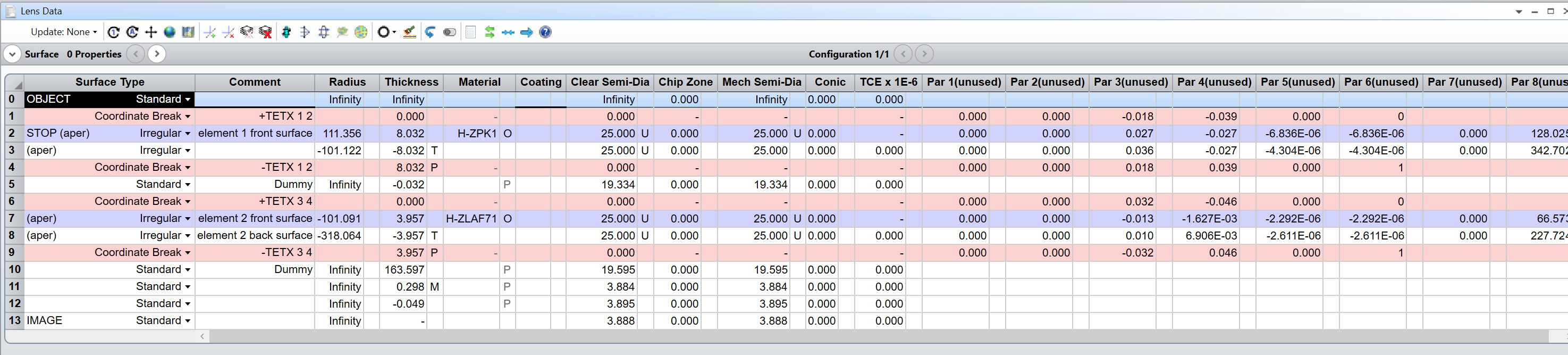

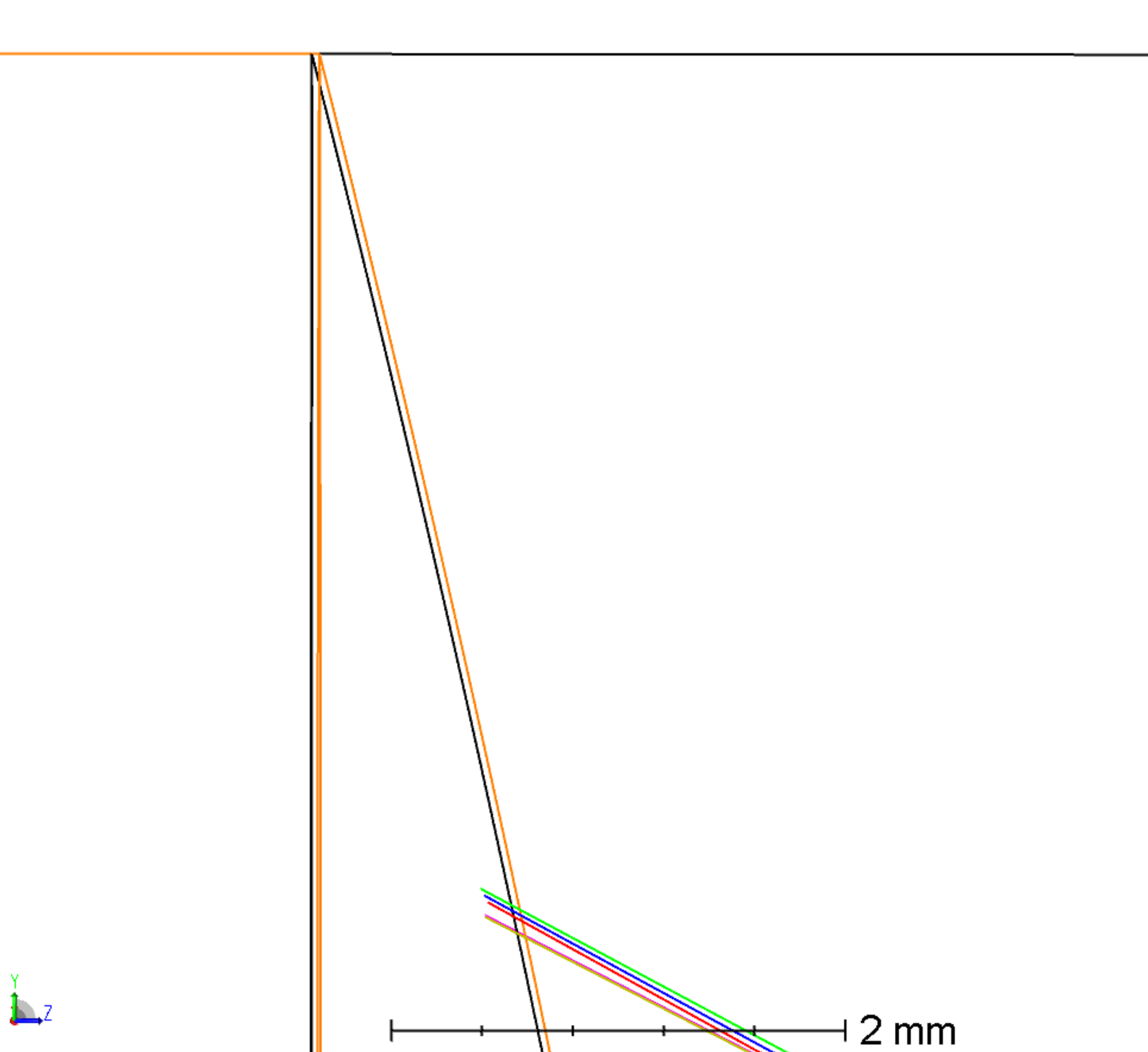

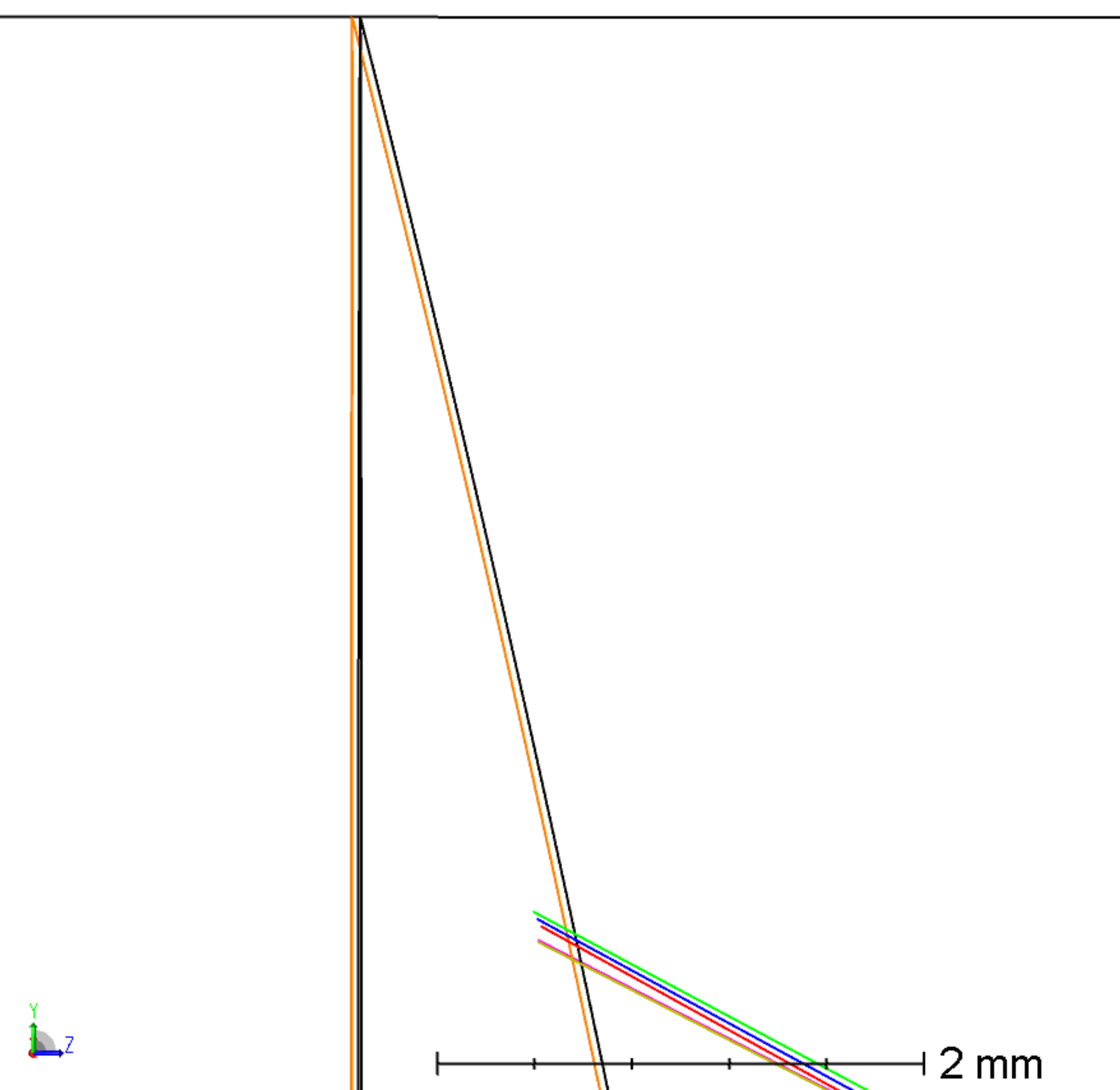

The first image below highlights the position of the back surface of the first lens element, and the second image highlights the position of the front surface of the second lens element.

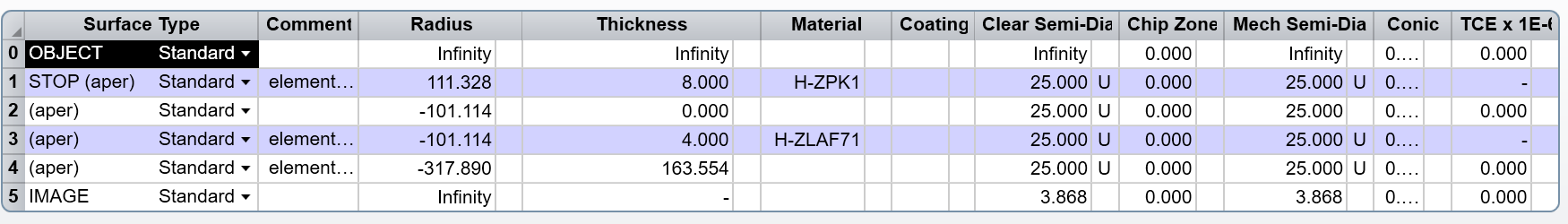

Additionally, before tolerancing the lens was modelled with 4 surfaces:

Any ideas/help would be appreciated.

Thank you,

Musab