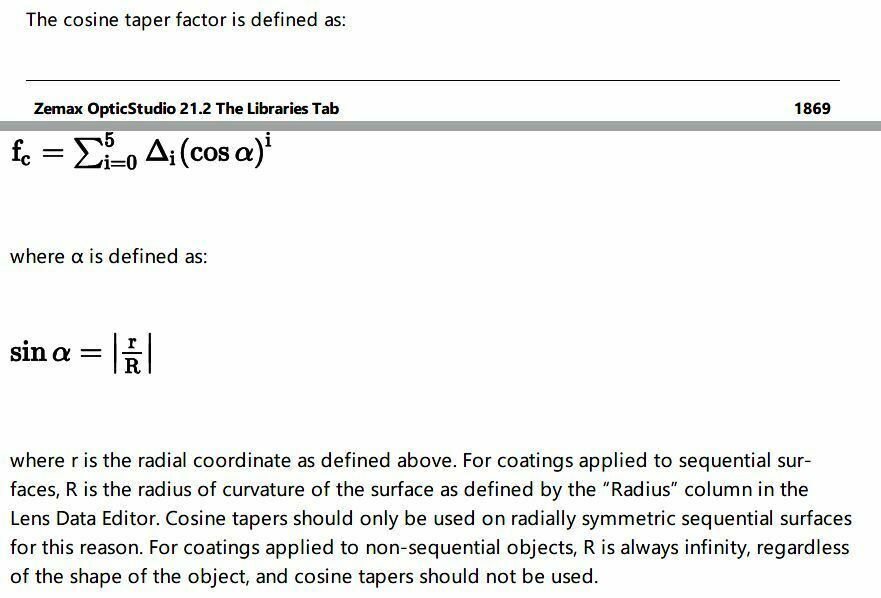

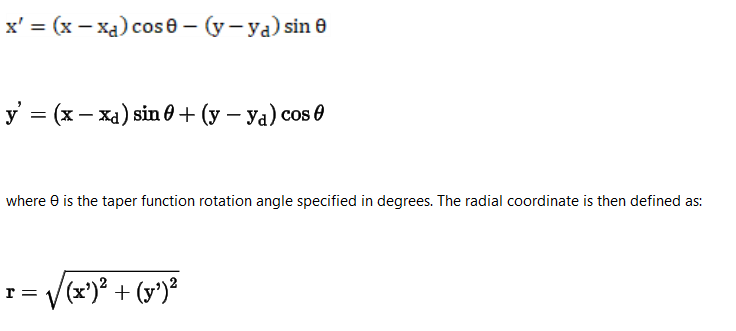

If I have a radius of curvature R = 0.865” and a surface semi-diameter of 0.75” and I apply a TAPR decenter DY of 0.25”, I’ll get a range of r going from -1.0” to 0.5”, which then gives sin(alpha) = abs(-1/0.865) = 1.156. Taking the asin of this gives me an error (in Excel). Am I doing this correctly? (All “x” components are “0” for this question, e.g. no DX involved). Thanks.

Alex