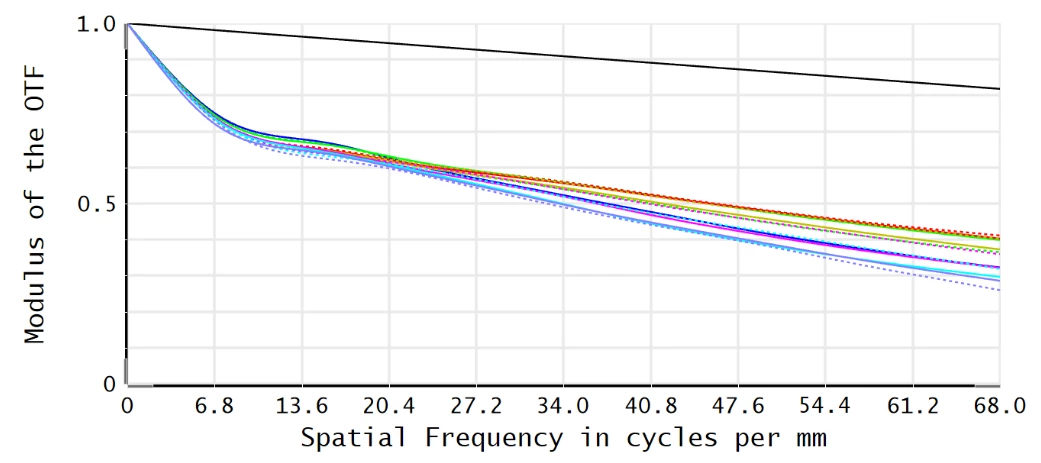

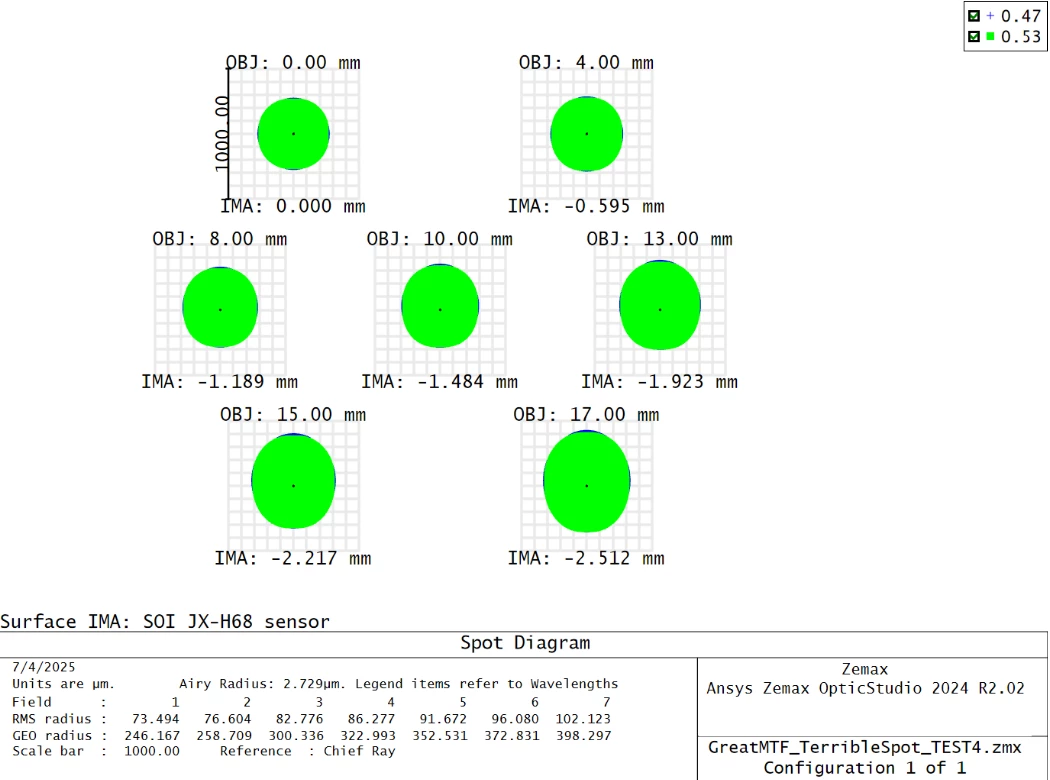

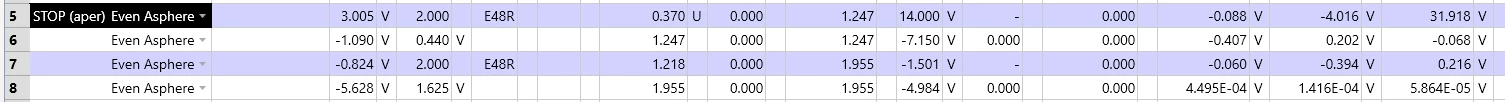

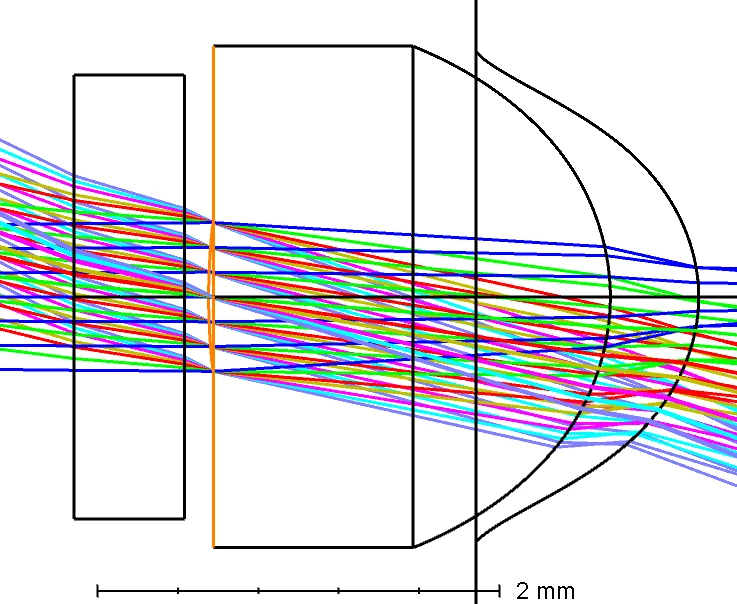

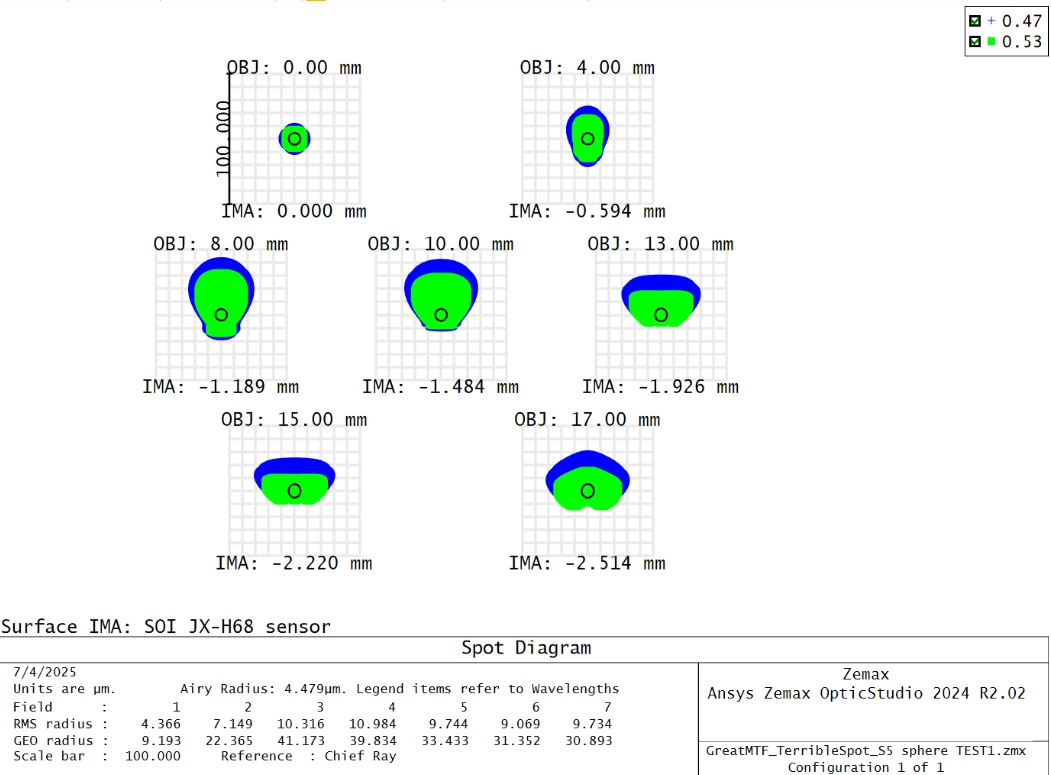

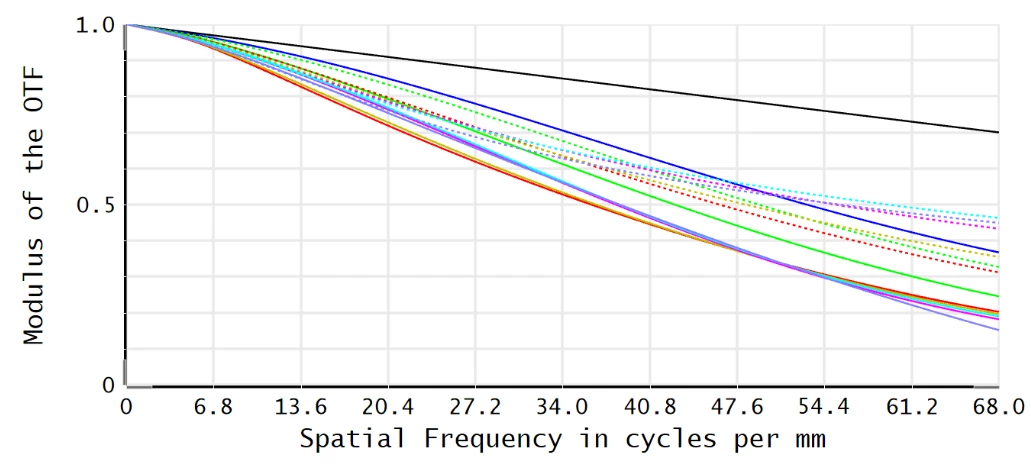

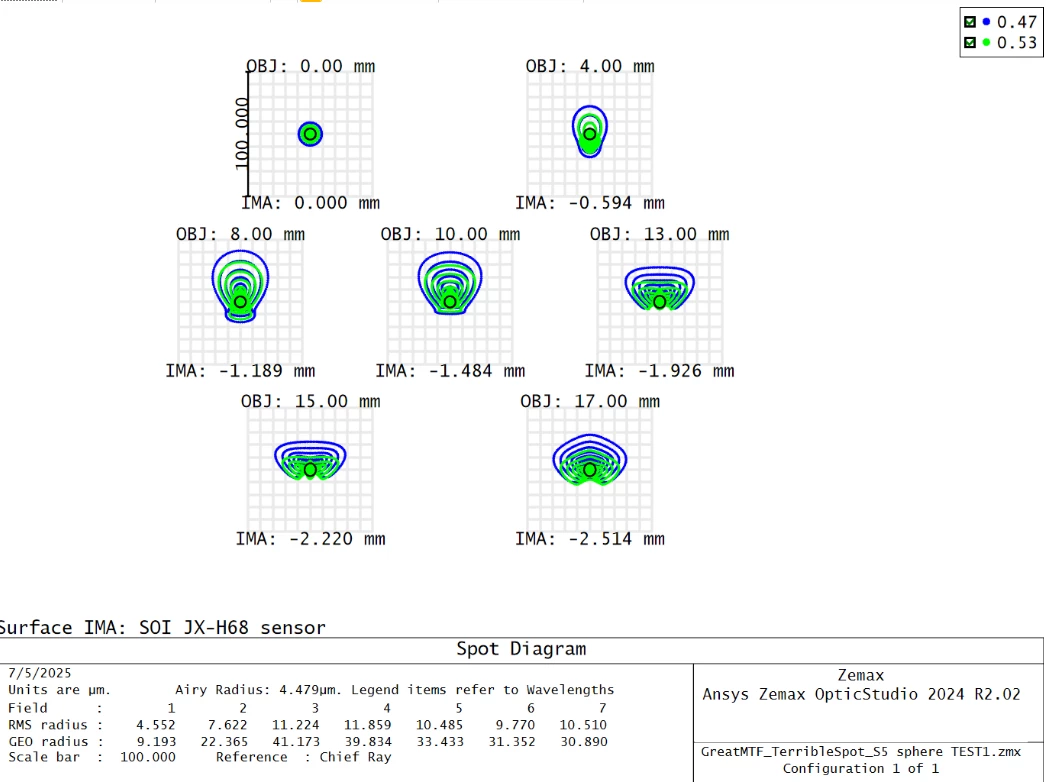

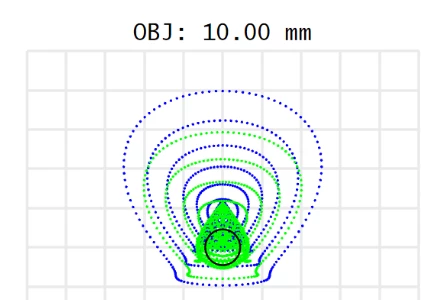

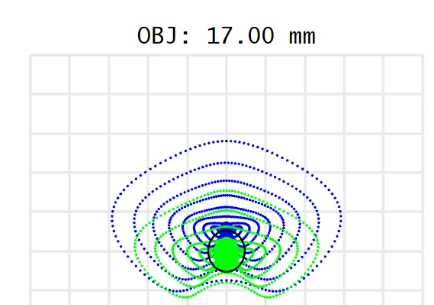

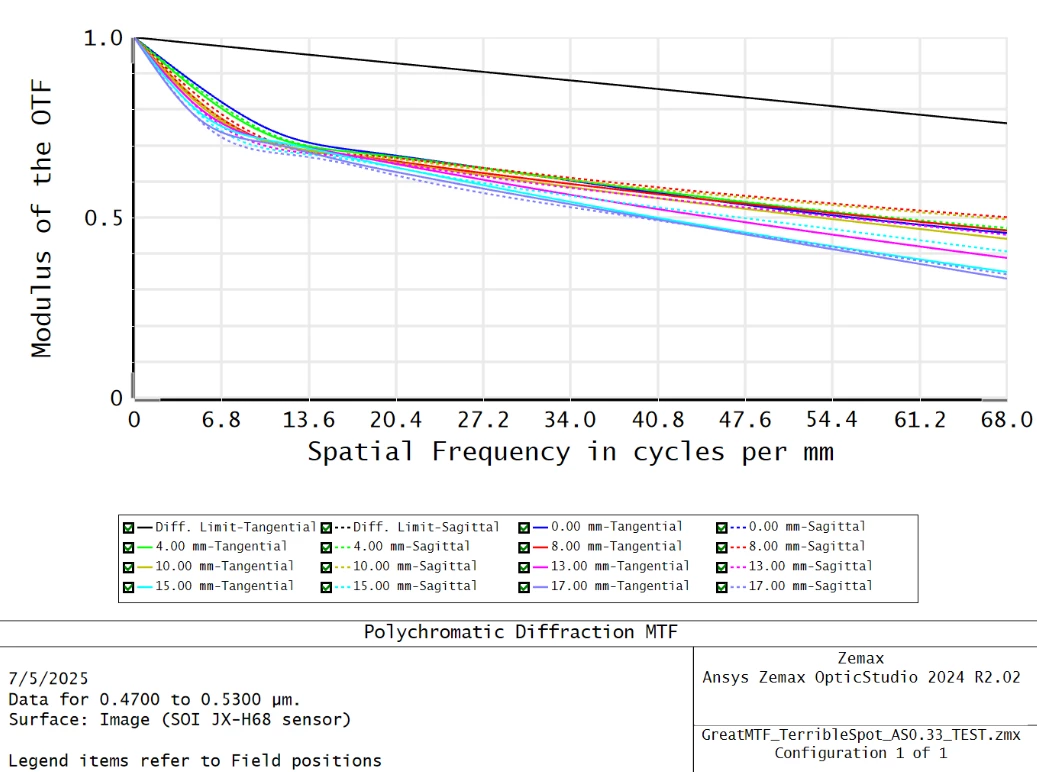

I used global optimization on a 2-lens imaging system with each lens having dual even asphere surface. The merit function improved a lot but now the diffraction MTF seems too good compared to how the rays look focusing in the 3D layout and how they look in the spot diagram. The only thing I can think is that since I have rather steep slopes to my lenses (due some high conic constants and one surface have high r^8 coefficient) that maybe there is some sampling issue. I did increase the ray density for the spot diagram and it does improve, but I am still concerned about the accuracy of the results I am getting. Any advice would be helpful -- Dan

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.