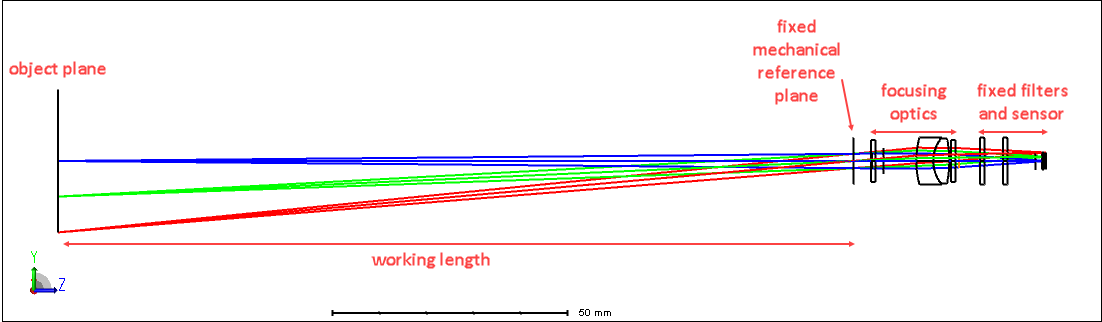

I have a simple lens system that has a fixed distance between a mechanical measurement datum and the sensor. A doublet + 2 windows is designed to accommodate object positions (working length) from 6 to -2 diopters when adjusted within its mechanical travel limits. Layout above is shown at 6 diopters.

I have large data set of measurements where the accommodation is shifted 0.5 diopters (5.5 to -2.5) from what is predicted by the Optics Studio model. I’ve checked with multiple sensors, a different focus lens with same focal length, and double checked all the mechanical dimensions. The focus travel limit position error for the 0.5 diopter shift is on the order of 0.010” and my measurement confidence is ~+/- 0.001”.

I’ve considered error from wavelength, focus criteria, dimensional measurements.

Is there any fundamental reason I shouldn’t expect better agreement between the model and measurements?

Any thoughts would be appreciated!

Thank you,

John