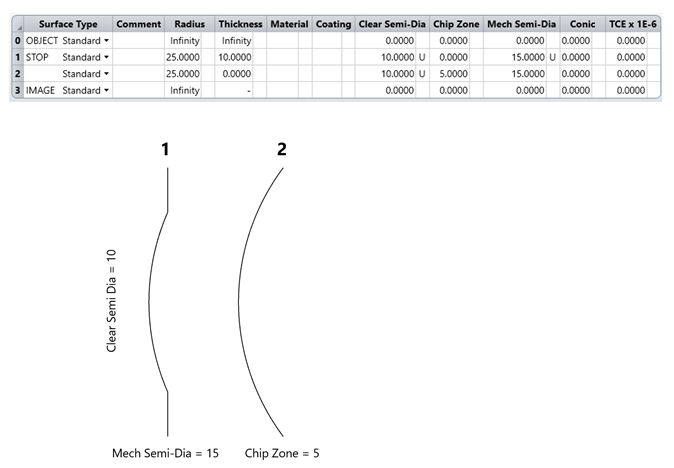

Hello! I have a question about increasing the mechanical semi-diameter of lenses. When I go into the lens data editor and increase the mechanical semi-diameter by some value, it adds little flat bits to the lenses without changing clear semi-diameter (or optical performance specs). See attached image.

This is probably exactly what we want, but I'm wondering also how one would increase the mechanical semi-diameter by extending the spherical surfaces, but not changing performance evaluation or clear semi-diameter. Naturally, extending the spherical surfaces would decrease edge thickness, and my merit function optimization would complain or change my design significantly, but we're just fleshing out our options.

Is my question clear? Thank you very much. Attached is an image of the flat extensions which, as I said, we may be happy with already.

Elliot

P.S. Actually, come to think of it, are there any known cautionary notes about manufacturing/mounting with flat edges like that? Intuitively, it seems almost better, but I have never mounted optics (yet!). This is for a satellite application, by the way.