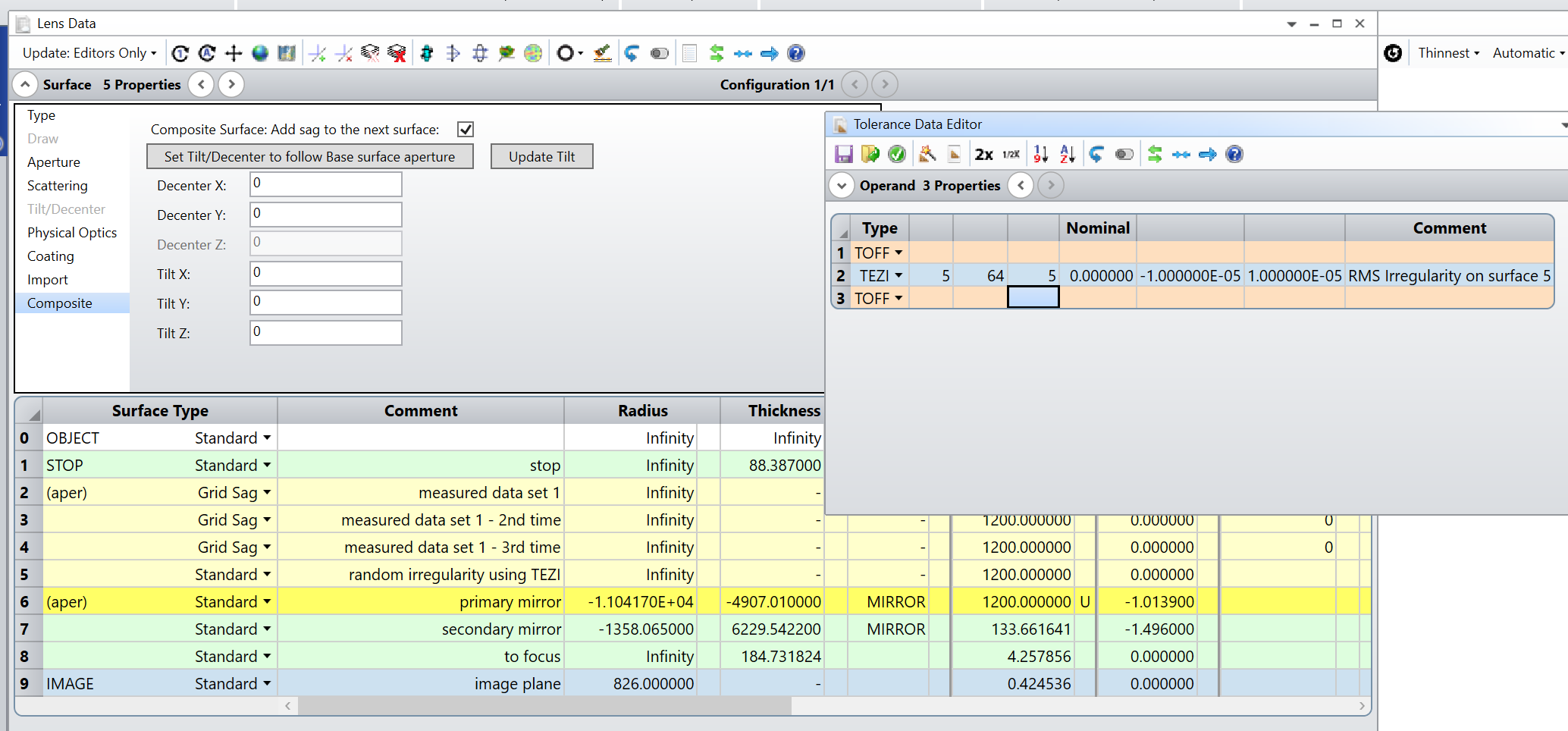

Hey friends, I am wondering how to set up tolerancing using composite surfaces.

Basically, I have a composite surface configured with the designed curvature of a lens as the base, and the Grid sag file generated based on errors I measured from a lens using profilometry. I would like to see if I have multiple times of the error adding on the base, how bad the lens performances will be. I was trying to use TIRR but I was confused about how to set it up. Can anyone suggest? Tutorial on ‘Tolerancing irregularity with Composite Surfaces’ was not very clear on this to me.