Hi all,

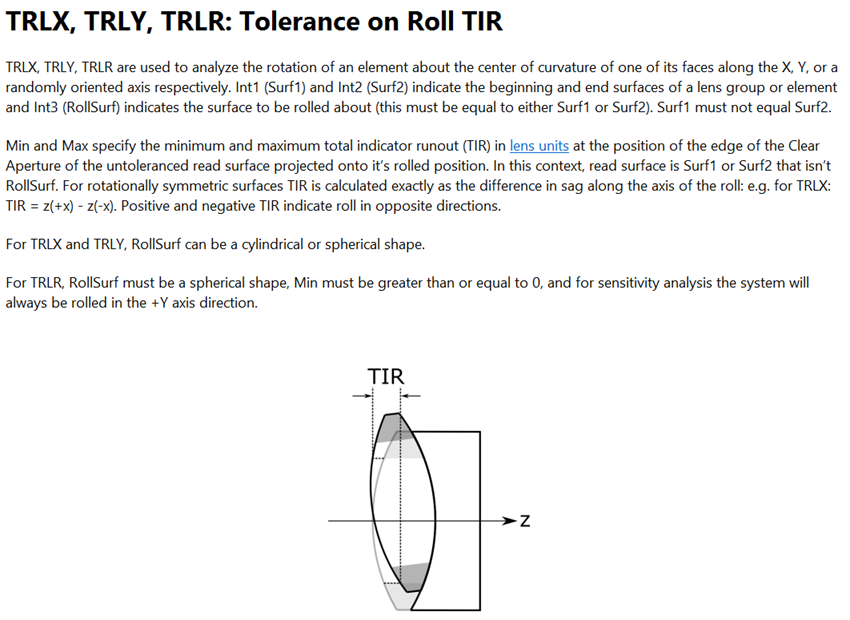

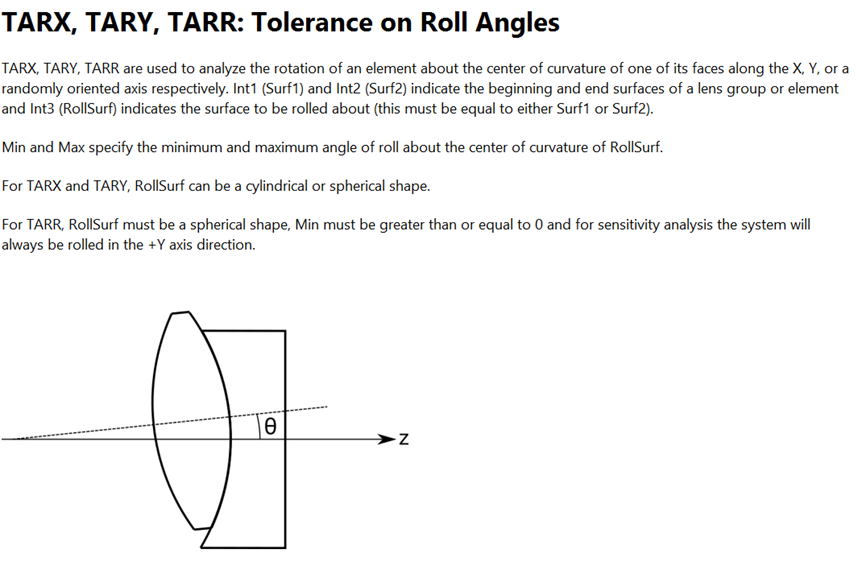

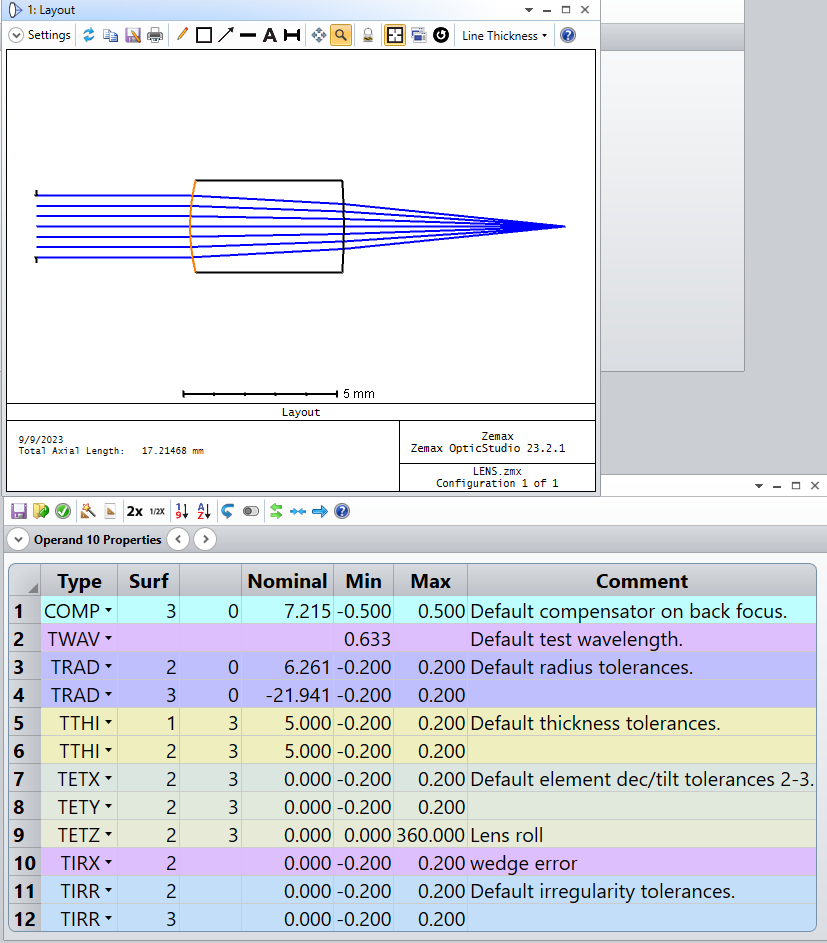

I try do a wedge tolerance analysis for sequential design with doublet lens. However, I couldn’t find the operands for it. Someone suggested me use TETX/TETY operands. However, the TETX/TETY is the tilt of the whole doublet group that pivoting its front surface vertex. Therefore, TETX/TETY tolerance operand is for alignment error. The wedge tolerance for doublets is more like doublet roll tolerance. Even though, both will cause optical deviation, I am not sure how correct to use TETX/TETY (alignment tolerance) for doublet roll tolerance. How you do wedge tolerance analysis? Any advices and thoughts are helpful.

Thanks,

Xiaolei