Hello,

I am currently simulating in zemax light recovery in an optical fiber in non-sequential mode. This fiber is in direct contact with a glass slide which has a complex thin-film coating on its surface. I am specifically trying to measure the spectrally modified signal that is re-coupled into the fiber. Using a macro, I’m able to sweep through all wavelengths and obtain the spectral signal by measuring at each wavelength the power re-coupled.

However, I know that the spectral response is highly angle-sensitive, and initial simulations show that moving the fiber away from the glass slide by distance less than the thickness of the coating changed the spectral response. Its fairly clear that the coating simulation in zemax does not account for any displacement of rays in the coating (which, admittedly, is OK for the vast majority of cases, but not for mine).

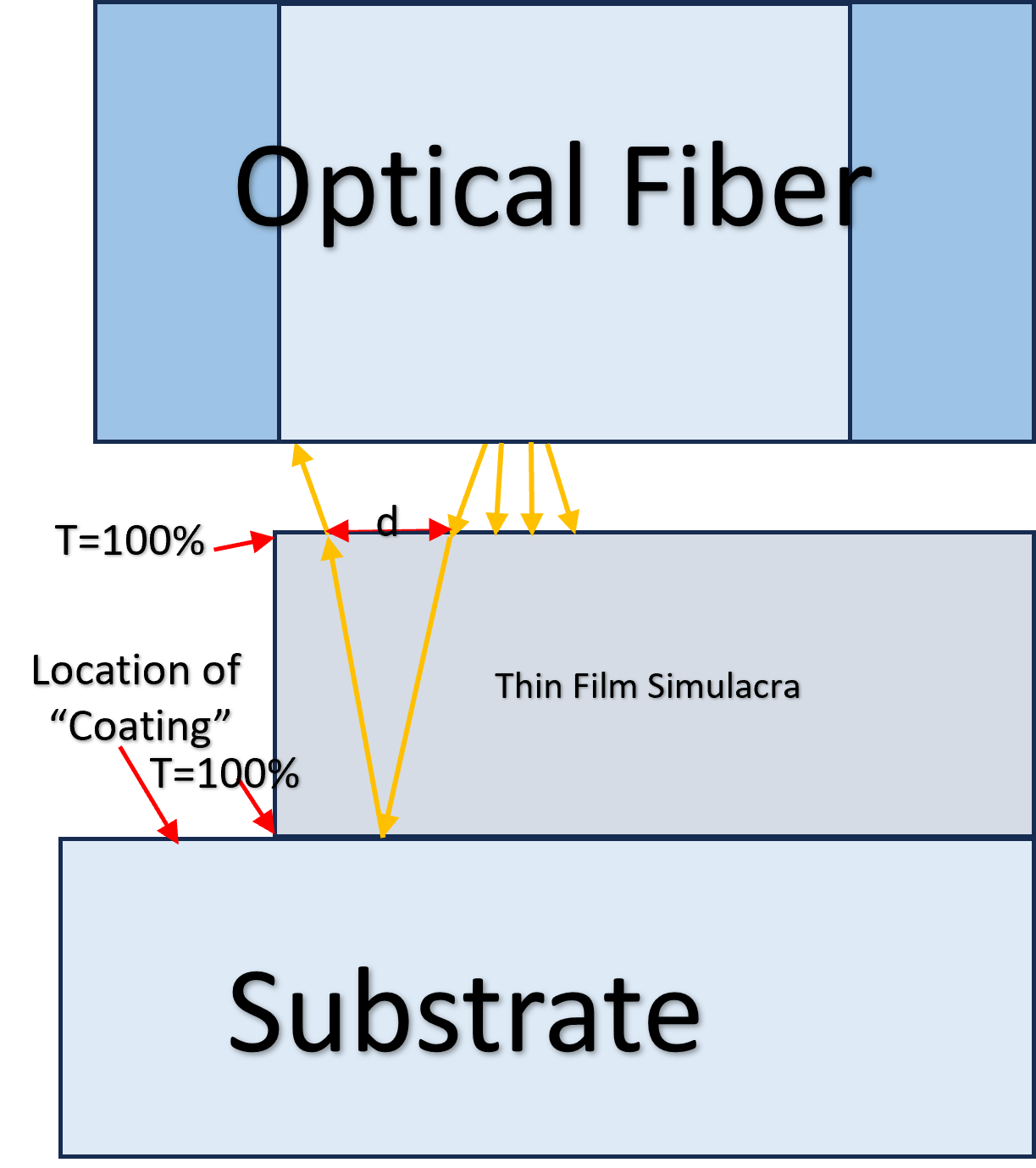

So, in a bid to have a more exact simulation, I’ve attempted to model displacement by creating a physical simulacra of the coating above the substrate. The “coating” aspect is simulated at the surface of the substrate, which each layer of the simulacra is considered to have a 100% transmittance. The simulacra displaces the rays, while each ray is affected a single time by the coating. An exceedingly small air gap (~100 nm) is left between the simulacra and the substrate to ensure the rays hit the coating at the same angle as they would normaly enter.

This remains a significant approximation. I’m essentially treating the wave-physics & ray-tracing parts of the simulation as separate. So as I havent found any extant examples of something similar, I have a few questions:

1) How to best approximate the displacement of rays within a coating?

2) Would any physical optics propagation tools function here? I am unexperienced with these tools, so I’m unsure. But I havent found any cases of POP being used to model thin films, so I’m doubtful.

2) How to best validate such approximations? (I am looking into getting some real coatings deposited for testing, but that does take time)

I know I’m doing something zemax was definitly not made for, but its the main tool I’ve got so I’m trying to get the most out of it.