Hey there,

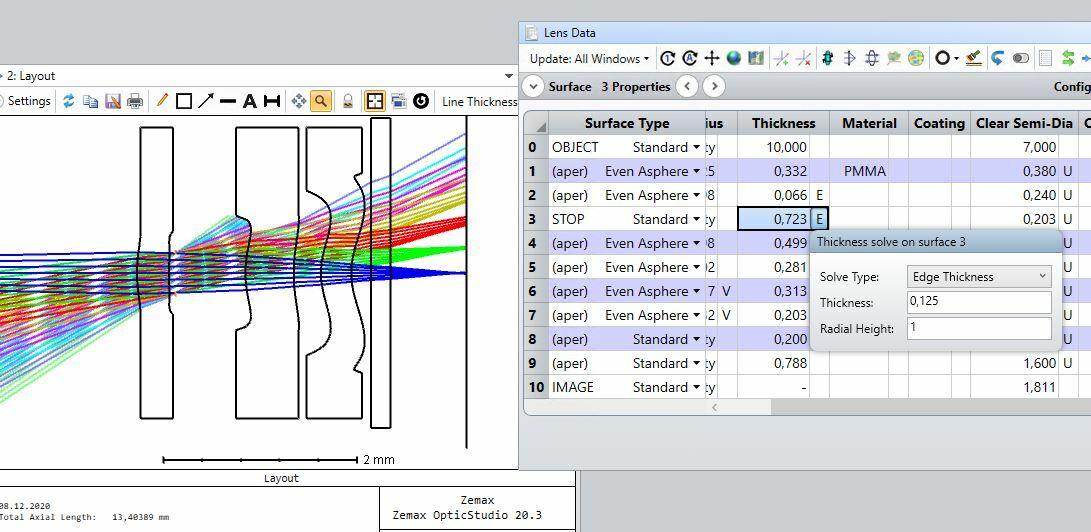

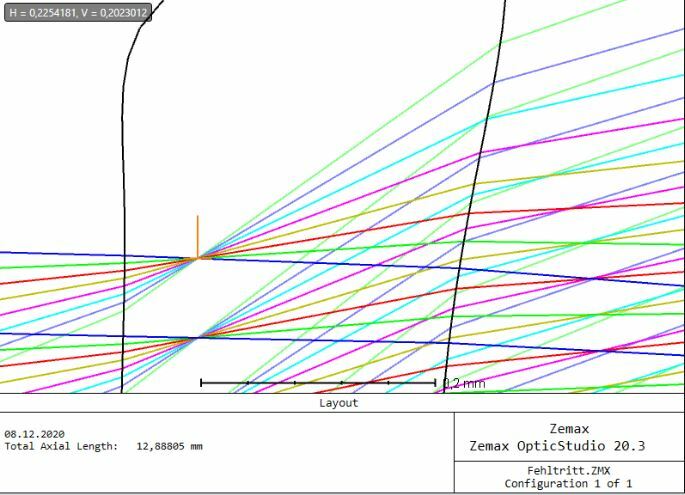

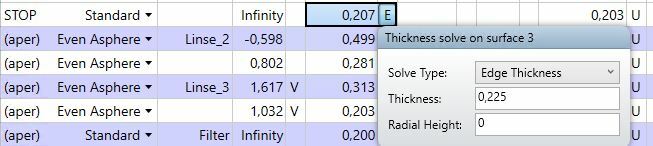

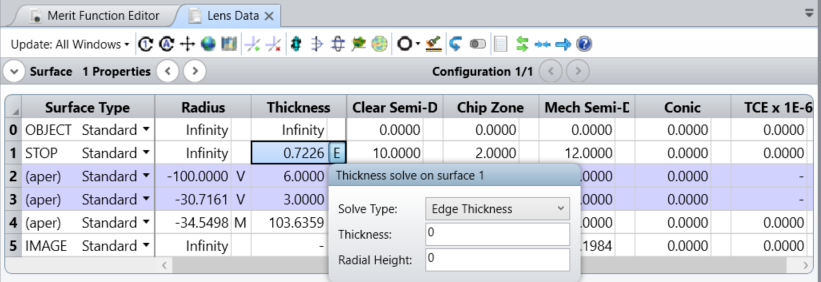

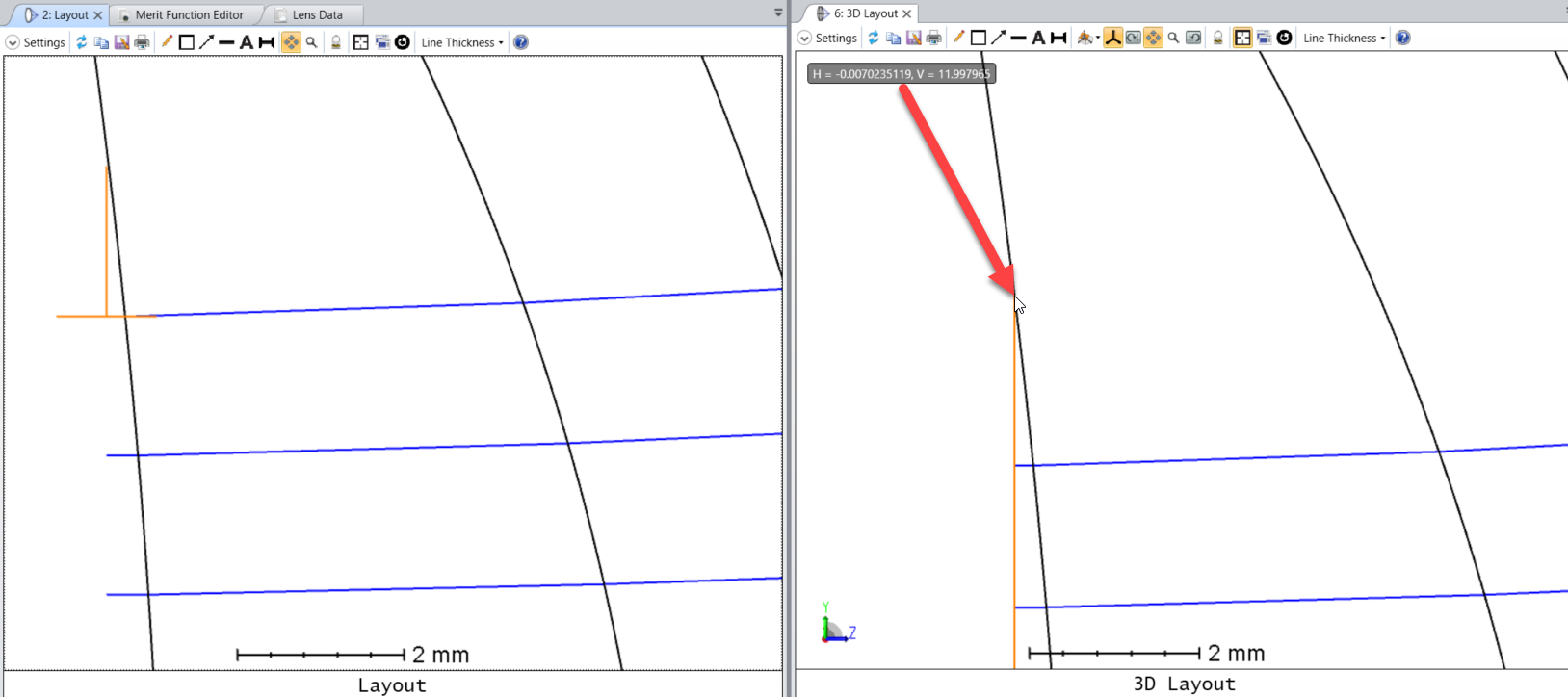

does anyone here know how to achieve a certain edge thickness at the full mechanical semi-diameter having chip zone turned on? Is there any possibility to use e. g. the edge thickness solve function in the lens data editor for the mechanical semi diameter as well? Everytime I try to set the edge thickness to a certain value the following surface removes itself an unpredicted long distance.

Thanks in advance.

Stephan