Hello, Zemax community!

I am interested in optimizing an optical system with an imported CAD model (collimator). Zemax knowledgebase has an excellent article explaining how to use dynamic model links ("Using the OpticStudio Dynamic CAD link"). However, only model parameters that are explicitly used in the model can be used in optimization. This slows down optimization when it comes to optimizing a surface profile that can be plotted using a few dozen points rather than a few polynomial coefficients. This is inconvenient when it comes to optimizing the surface profile, which can be constructed using several tens of points or several polynomial coefficients. Unfortunately, the curve equation coefficients specified by the user in the CAD program are not displayed in OpticStudio. Is there any way to use user-defined parameters of the CAD model in the optimization process in OpticStudio?

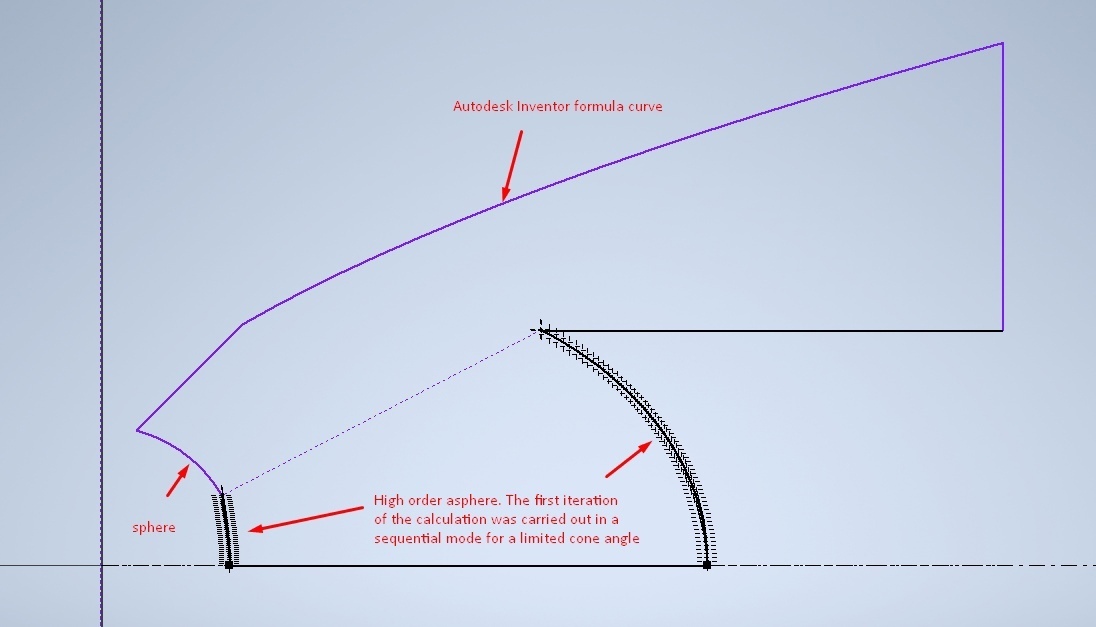

Best answer by Flurin Herren

View original