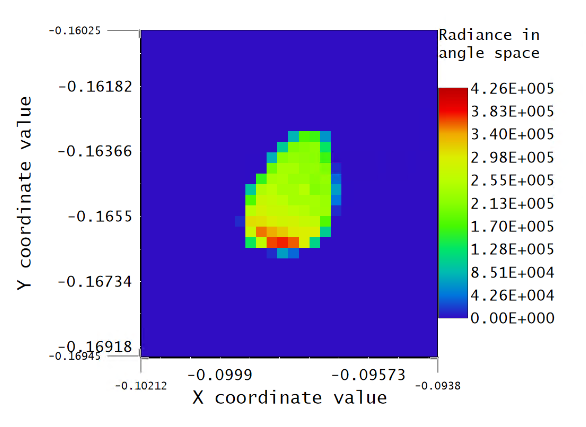

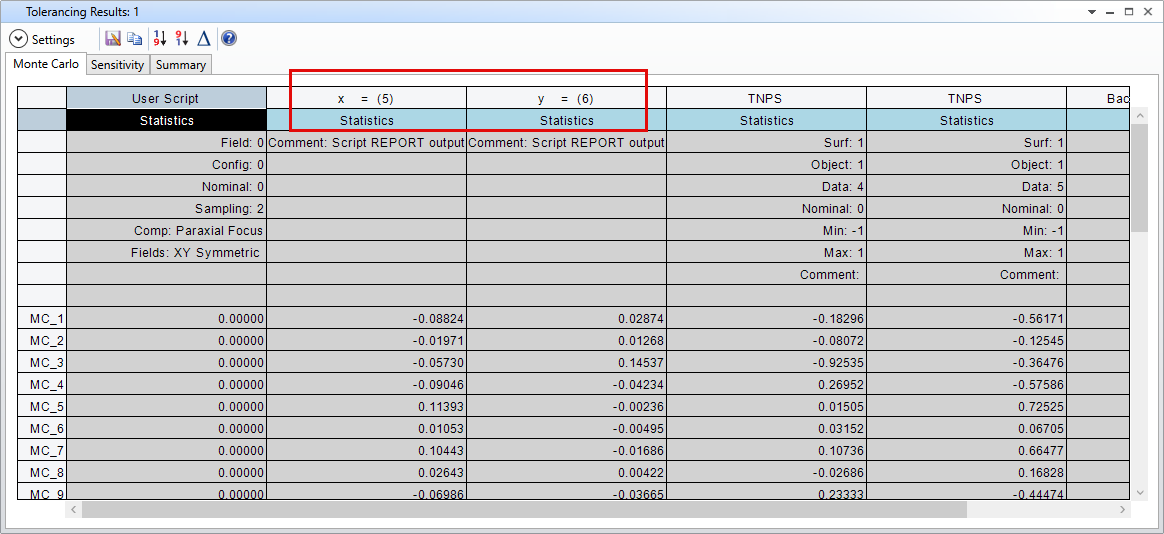

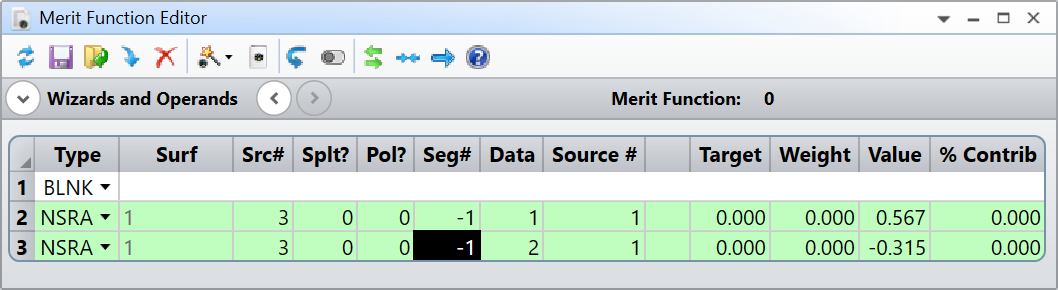

I am trying to perform a tolerancing analysis of a complex illumination system consisting of lots of flat and powered mirrors which expand the output into a large (about 30 cm) output beam. I am trying to establish how many compensators are required in the system to maintain good collimation of the output beam when reasonable manufacturing tolerances are applied. Therefore I am using a merit function which is the RMS angular radius at the output. I want to measure this down to sub-arcsecond levels of precision. However, I am relatively un-interested in the actual direction of the output beam. Applying a set of tolerances to the optical components in my system cause the output beam direction to drift a lot relative to the change in the collimation of the beam and so in order to measure the beam I must use a detector rectangle with fairly broad range of angles (in this case I am using +/-0.3 degrees). The problem is that even with the maximum number of pixels for the detector rectangle object, the resolution is too low to properly resolve the collimation in most cases.

Is there a way to achieve high resolution for sampling the collimated beam, while also being able to detect the beam over a wide range of beam angles?

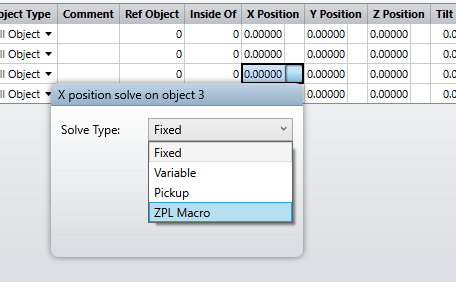

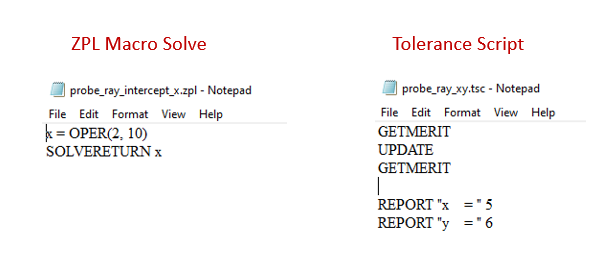

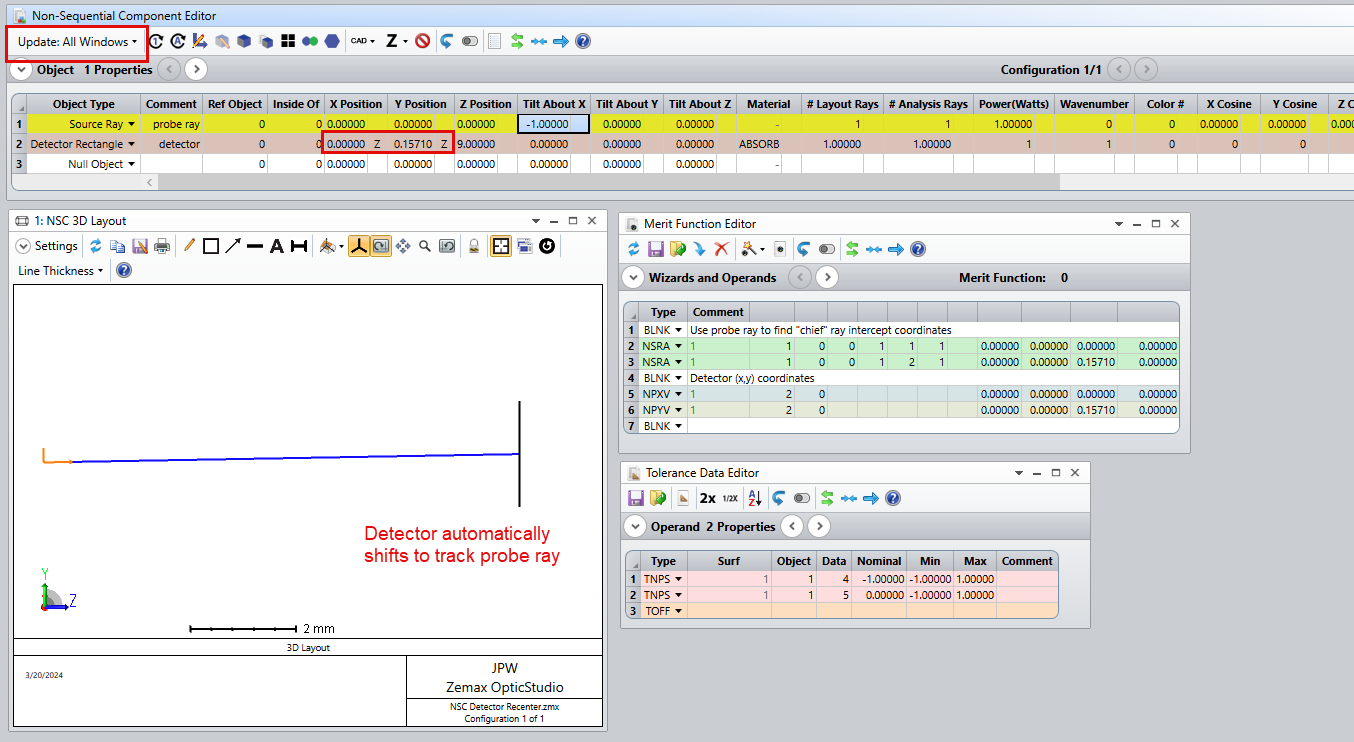

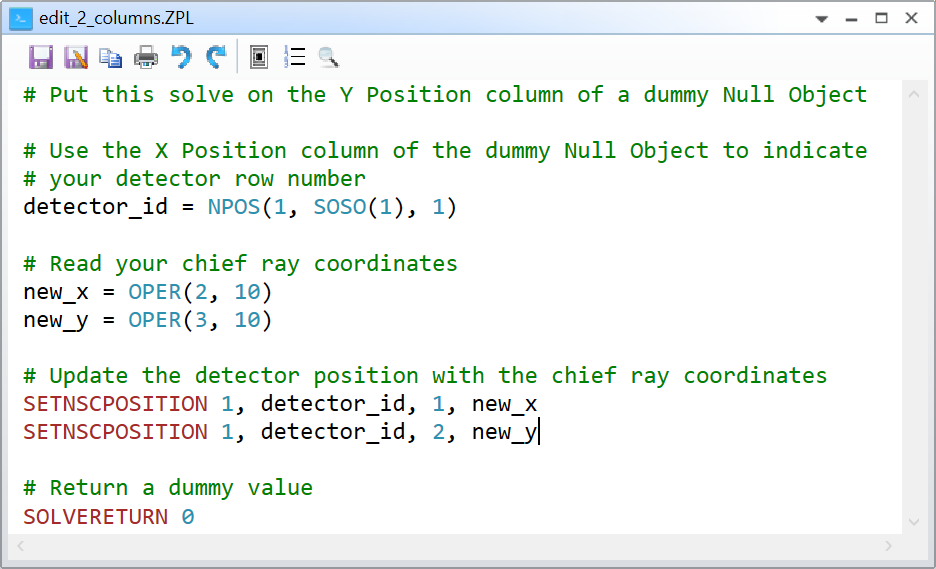

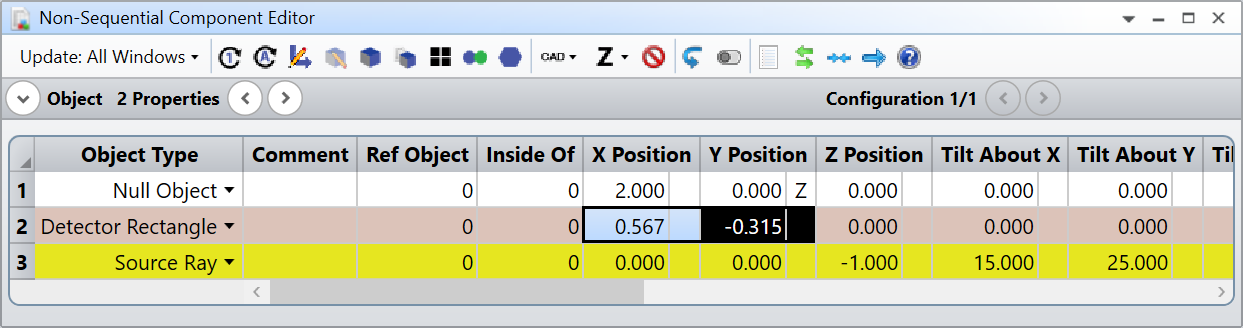

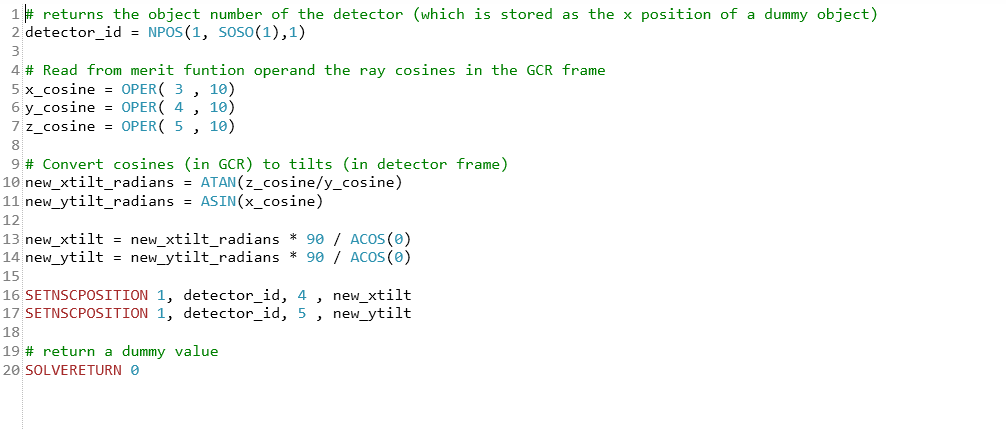

The most simple solution I can think of is to have the detector co-moving with the output beam such that the chief ray hits the centre of the detector. Is there a way to implement this in NSC mode?