Hi

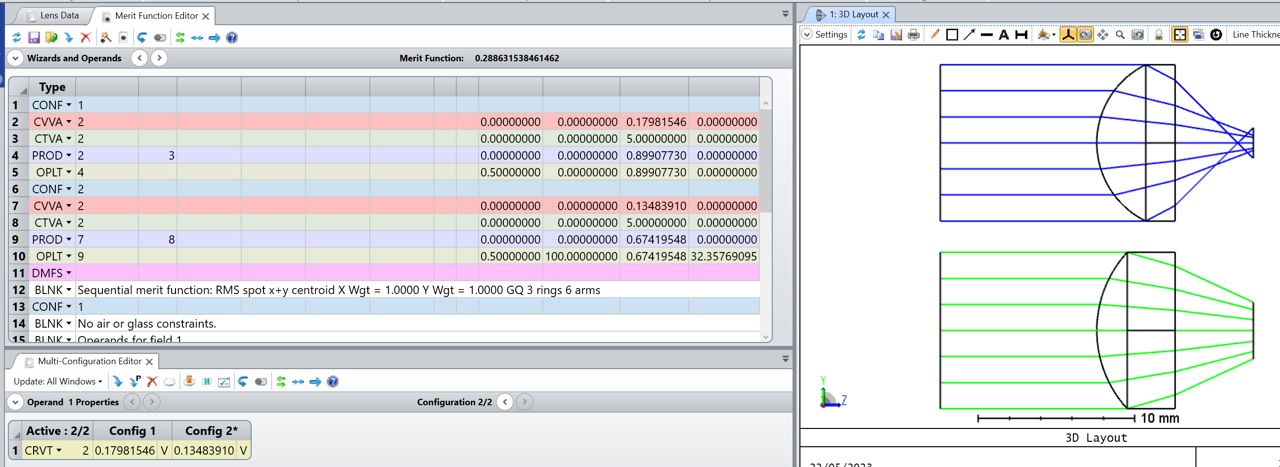

I want to check how should we limit the diameter-to-radius ratio in Zemax? I’m using MNCG and MXCG to limit the thickness of the lens. However, during the optimization process, the lens radius can be negative and the absolute value is larger than the lens thickness which make these lens not real. Could we use some operand to avoid the situation? I’m trying to find the operand to get the radius and limit the thickness according to the radius but failed to find the operand. Do we have other operand to do that?

Thanks!